SCM Group Minimax 230V Single Phase 23-fpm Pre-Milling Automatic Glue Pot Edgebander with Full Corner Rounding ME 35ETR

| Manufacturer Part: | EMT ID: |

|

ME 35ETR-1ph

|

19807

|

- Worktable dims: 118.06” x 20.62”

- Worktable height: 35.56”

- Thickness of rolled edges: 0.4 - 3mm (0.02” - 0.06”)

- Thickness of edges in strips: up to 5mm (0.19”)

Description

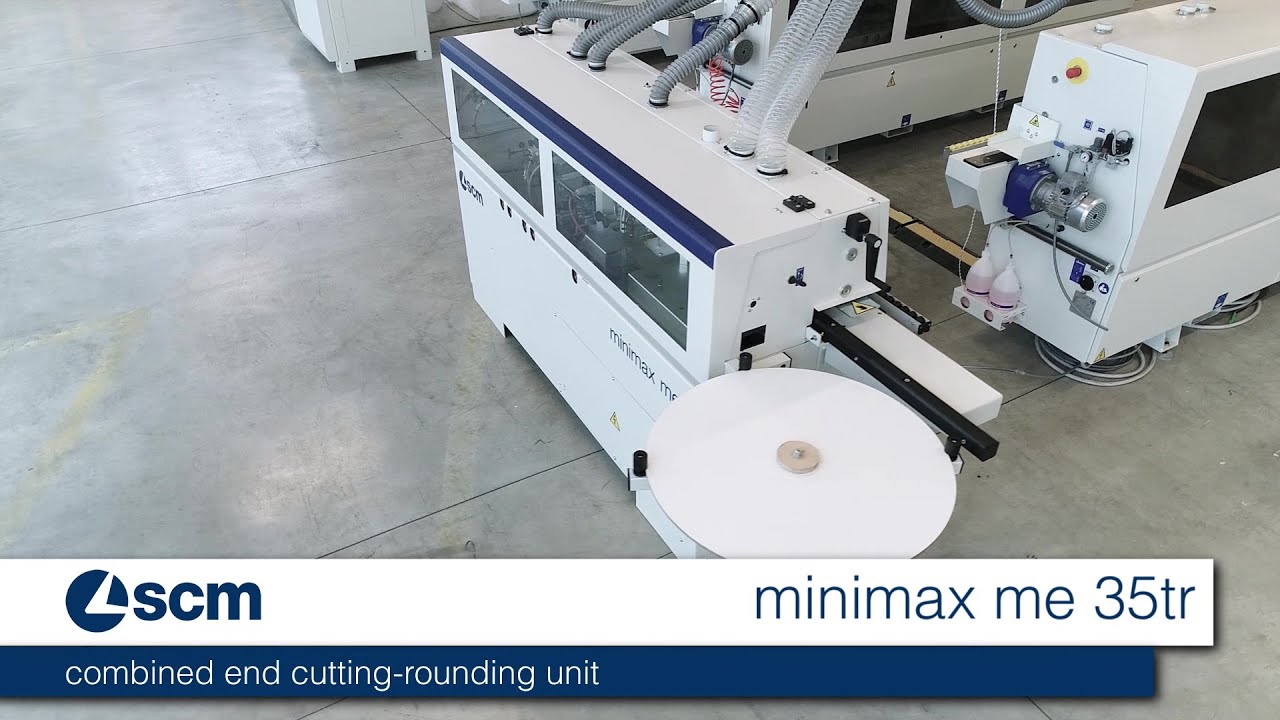

The Minimax ME 35ETR is a 3-phase automatic edge bander with great flexibility for both thin and thick edges, intended to bridge the gap between a traditional small to mid-sized edge bander for woodworkers; to the more robust equipment used in the Classical line of products. Two of the key features are the pre-mill and corner rounding units. There is no competition in the U.S. market for such a small, versatile machine, with pre-mill or corner rounding that is so economical! This machine is meant to be used with melamine edges, PVC, and ABS up to 3mm. This amazing machine boasts capacities usually only found on much larger and expensive machines.

Designed for a perfect finish

A new combined end cutting-rounding unit with rigid structure for unique quality processing in its market segment. Now the rounding process is available for all workshops

Perfect edge cleaning

The glue is heated rapidly and evenly by the resistances. The automatic lowering of the glue temperature after a temporary halt in production when using the machine avoids burning of the glue. A new innovative system of self-lubrication of the glue pot, allows a more extensive use of the edge banding machine without the necessity of lubrication. Two rollers press the edge banding evenly and efficiently on the panel edge. The glue spreading roller with electrical resistance inside provides a uniform glue spread and always at the maximum working temperature even on panels at the maximum working height

Brilliant idea

The optional unit allows you to make a radius on the corners of the edged panel without the need for the operator to have to finish by hand at a later stage: brilliant idea for a finished product of high quality

Pre-Milling Unit

Complete with (2) diamond tools, 80 mm diameter. It allows a very good panel finish and linearity during pre-machining. It is equipped with independent exhaust hoods and an air blower which cleans the panel from dust and chips

Glue Pot Unit, Edge Loading and Pressing System

- Hot melt glue with quick heat up system and internally teflon coated to allow an easy glue replacement

- Glue application on the panel by means of glue spreading roller

- Temperature adjustment of the applied glue integrated in the PLC control

- Device for automatic recovery of unused glue

- Automatic edge loading system for rolled edges with shear device for 3mm max thickness edges

- Coil holder plate, 730 mm diameter

- Pressing unit with n. 2 edge steel rollers with counterposed conicity

- Adjustable infeed fence with numeric readout

- Automatic lowering of the glue pot temperature after a temporary non-use of the machine

- Self-lubrication system of the glue pot

Combined End Cutting-Rounding Unit

- End cutting of front and rear exceeding edge

- Full rounding and corner rounding

Top and Bottom Trimming Unit

- High frequency motors

- Front rotating copiers with chrome plated surfaces and vertical copying discs for an accurate positioning of tools with reference to the cutting point

The unit is provided with 55.3 mm diameter combined cutters

- The radius part of the cutter is used to trim radius edges (1-2-3mm) and chamfered thin edges

- The straight part of the cutter is used for the trimming of edges in wood up to 5mm

Changing from radius edge to edge in wood is done easily by moving the cutters. The edge thickness is displayed on 2 numeric readouts

Edge Scraping Unit

It assures an excellent vibration free finish thanks to its high rigidity structure. High working precision thanks to the horizontal and vertical copying discs, which assure an accurate positioning of the knives in relation to the cutting point. It allows the finishing of 1-2-3mm PVC/ABS edges. Pair of knives included

- Numerical readout for the positioning

- Manual exclusion of the unit

Brushing Unit

Tilted, vertically adjustable motors to optimize the cleaning and polishing of the edge

Features

- “Eye-S” touch screen control: optimal managing of the machine thanks to the new 10” touch screen control panel with Maestro active edge, where all of the machine functions are graphically shown

- Combined end cutting-rounding unit: this special unit removes the front and rear exceeding edges and performs full corner rounding in a single pass. It is automatically control ed from the “Eye-S” panel

- Versatility and ease of use: take advantage of the numerous options and accessories that can be equipped on the ME 35ETR

- Safety/Protections

- Safety enclosure

- Main power switch can be locked in the off position with a padlock

- Emergency pushbutton located on the control panel

Standard Equipment

- Eye-S 10” touch screen control on machine infeed side

- Maestro active edge interface

- Immediate and intuitive panel programming thanks to the adaptive 3D design of the processing with real time preview

- No possibility of error with the machining guidance system that suggests the correct machine set up to the operator

- Machine frame made of high rigidity ribbed steel to guarantee an excellent support for the operating units

- Kit for glue pot rapid substitution which includes the rapid locking/unlocking device and the double thermoregulation system to manage two different working temperatures (ex. For the polyurethane glues use)

- Top thick steel pressure beam with rubber coated wheels

- Panel support roller which can be extended on the entire length of the machine

- Numeric indicator of the selected panel thickness

- Manual adjustment of top beam with automatic positioning of the operating units according to the selected panel thickness

- Units included: pre-milling, glue pot, end-cutting/rounding, T/B trimming, profile scraping, buffing

- 2mm radius tooling set and (2) pre-mill diamond cutters included

- Toolbox: wrenches, allen wrenches, user manual, spare parts catalog

Specifications

- Worktable dims: 118.06” x 20.62”

- Worktable height: 35.56”

- Thickness of rolled edges: 0.4 - 3mm (0.02” - 0.06”)

- Thickness of edges in strips: up to 5mm (0.19”)

- Min/Max panel height: 8/50mm (0.31”/1.94”)

- Min panel length/width with rolled edges: 120/110mm (4.75”/4.31”)

- Feed speed: 23 fpm

- Feed motor power: 0.9 kW

- Operating temperature: 68 - 374° F

- Pre-Milling Unit

- Motor: 3 kW – 7,200 rpm

- Diamond cutter: 2 x Ø 80mm H=56 Z2

- Stock removal: 0.5 / 1 / 1.5 / 2mm (0-0.08”)

- Glue Pot Uni

- Motor: 0.3 kW

- Glue capacity: 2 lbs

- Combined End Cutting-Rounding Unit

- Motor: 0.2 kW – 12,000 rpm

- Blade: Ø 125mm Z12

- Top and Bottom Trimming Unit

- Motor: 0.35 kW – 12,000 rpm

- Cutters: Ø 58mm Z4

- Brushing Unit

- Motor power: 2 x 0.14 kW – 2,800 rpm

- Exhaust outlets diameter

- No 2 pre-milling unit outlet: 3.12”

- No 1 glue pot outlet: 2.31”

- No 1 end cutting/rounding unit outlet: 2.31”

- No 2 trimming unit outlets: 2.31”

- No 1 grooving unit outlet: 2.31”

- Nominal extraction air consumption: 890 CFM

- Air exhaust speed: 66 ft/s

- Pneumatic operating pressure: 6.5 bar

- Electrical Requirements: 230V Single Phase 60Hz 37A

- Machine Dims: 103” x 37” x 61”

- Approx Weight: 1,530 lbs

Optional Add-Ons

- 1mm radius tooling set

- 1.5mm radius tooling set

- 3mm radius tooling set

- Internal machine lightening

- Spare glue pot

- Spare glue pot for EVA glue with fast unloading system

- Spare glue pot for PUR glue with fast unloading system

- Device for the panel edge heating

- Infrared ceramic lamp

- Glue scraping unit

- Anti-adhesive unit

- “Nesting” copying device kit for Trimming unit

- “Nesting” copying device kit for Edge Scraping unit

- Edges storage

- Edges storage with heating function

- Trimming unit with automatic on/off system

- Trimming unit with multiradius tool

- Edge scraping unit with automatic on/off system

- Edge scraping unit with multiradius tool

- Glue scraping unit with automatic on/off system

- Scoring unit for grooves execution

- Wireless barcode reader

**This machine requires a mandatory installation and training from the manufacturer. This comes as an additional charge that is NOT included in the website price. This additional charge includes the installation and full training on how to operate and maintain the machine. Please contact one of our sales representatives for more details**

| Manufacturer | |

| SKU |

ME 35ETR-1ph

|

| Shipping Method |

Flatbed

|

| Weight |

1,530 lb

|

| Dimensions |

101 × 35 × 59 in

|

| Country of Origin |

Italy

|