Marvel Amada 5 HP 230V Three Phase Vertical Tilt-Frame Band Saw 8-Mark-III VT4555M

*Image may display optional items not included with purchase.

| Manufacturer Part: | EMT ID: |

|

VT4555M

|

13128

|

- All-Mechanical Design

- Cast Iron Construction

- Large Adaptable Work Table

- Semi-Automatic

Features

- Controls - IEC fused disconnect switch and magnetic motor starters, with overload and low-voltage protection. Disconnect is NFPA79 compliant. DC Power supply provides low voltage control (24 Volts) to all push buttons at operator’s control panel and machine lighting circuits. PLC control and components mounted in moisture proof NEMA 12 compartment. Electrical Panel is UL labeled.

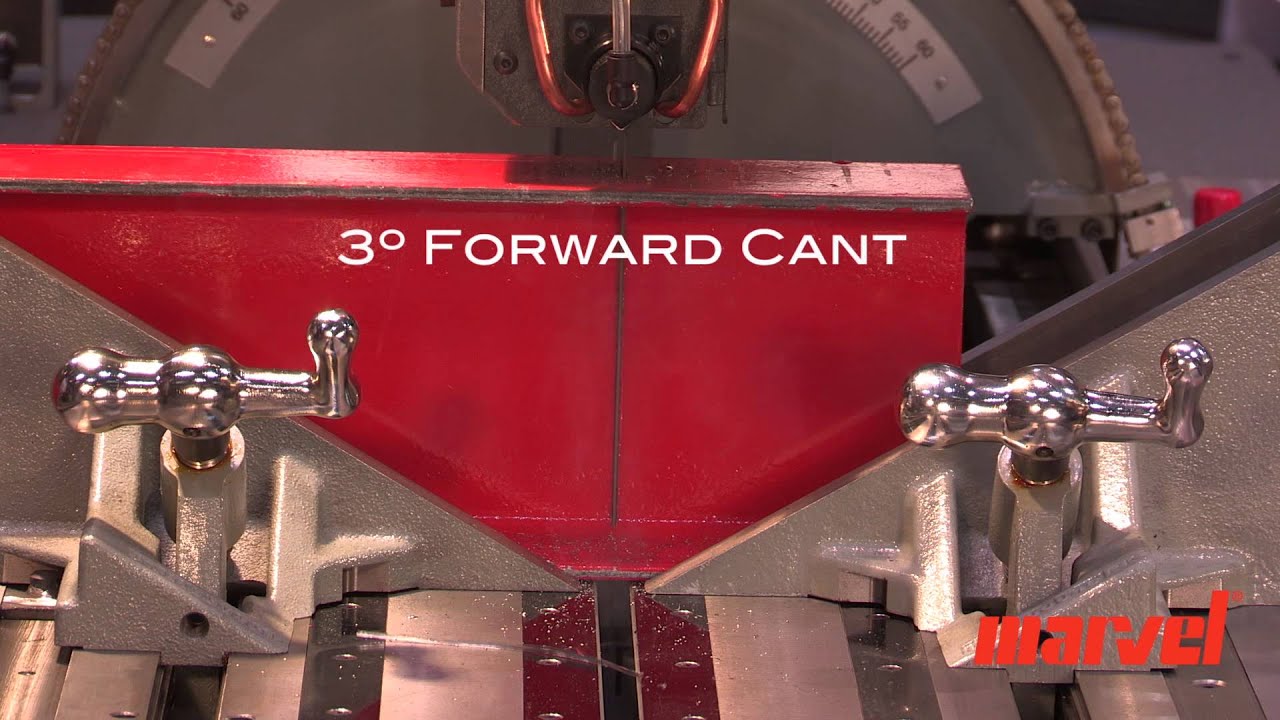

- Saw Column - Marvel’s patent pending Quick Change Column is standard on all machines. Allows column to be set either upright or at a 3° forward cant. (8-MARK III model only) Column travels on recirculating linear ball bearing rails.

- Mitered Cutting - Column and blade tilt right and left of vertical; work always stationary. Manual tilt standard with Sure-Lock and Built-in protractor. Electric Power tilt optional.

- Coolant System - Built In with flood system, available with added optional drop lubrication system (Option Codes ML1 & ML2). Controlled by on-off selector switch at operator’s station. Tank capacity 21 gallons (79 liters).

Specifications

- CAPACITY at 90°: 18" x 22"

- CAPACITY at 45° RIGHT: 18" x 14.5"

- CAPACITY at 45° LEFT: 18" x 13"

- CAPACITY at 60° RIGHT: 18" x 9.7"

- CAPACITY at 60° LEFT: 18" x 7.3"

- SPEED RANGE: 50 - 450 fpm infinitely variable with inverter drive.

- FRONT MOUNTED SPEED CONTROL: Allows blade speed to be adjusted from operator's control station.

- FEED RANGE: 0 - 250 lbs. infinitely variable with control on operator's panel and Automatic Column Return.

- T-SLOTTED WORK TABLE: Work area 24.25 x 33"; Table height 38"; Two machined T-slots.

- WHEEL DIAMETER: 19" cast iron wheels.

- BLADE BREAK/STALL DETECTION: Standard equipment shuts off machine in the event of blade breaking or stalling.

- MITER CUTTING: Column and blade tilt up to 60° right and left of vertical; work always stationary. Manual tilt standard with Sure-Lock and Built-in protractor. Electric Power tilt optional.

- SAW COLUMN: Amada Marvel patent pending Quick change Column is standard on all machines. Allows column to be set either upright or at a 3° forward cant. Column travels on recirculating linear ball bearing rails.

- QUICK-ACTION VISE: Maximum opening 18". Jaws can be shifted to either right or left side of blade. Jaws are 6" high, 12" wide.

- AUTOMATIC STOPS: Adjustable stops can be pre-set to stop advance and return of blade, and also to stop motor at any location within the 18" travel of the blade.

- COOLANT SYSTEM: Built in with flood system, available with added optional drop lubrication system. Controlled by on-off selector switch at operator's station. Tank capacity 21 gallons.

- FLUSHING HOSE: Washes chips from hard to get at places reducing clean-up time.

- POWER CHIP BRUSH: Together with blade wipers and flood coolant deep blade teeth free of chips.

- CARBIDE GUIDE SYSTEM: Solid carbide post design equipped with Patent Pending Amada Marvel Easy Load Guide Blocks. Upper and lower guides have preloaded carbide faced back-up blocks to support back edge of blade.

- BLADE: 15' 4" Long x 1.25" Wide x .042 Thick

- BLADE TENSION: Blade tension ratchet stops automatically at factory pre-set, 40,000 psi.

- MOTORS: Main: 5 H.P., 1800 RPM, totally enclosed fan cooled. Coolant Pump: 1/8 H.P. enclosed motor-built-in integrally.

- Voltage: 230 volt, 3 phase, 60 Hz.

- CONTROLS: IEC fused disconnect switch and magnetic motor starters, with overload and low-voltage protection. DC Power supply provides low voltage control to all push buttons at operator's control panel and machine lighting circuits. PLC control and components mounted in moisture proof NEMA 12 compartment. Electrical Panel is UL labeled.

Options:

- POWERED COLUMN TILT: Provides powered tilting of saw column up to 60° to both right and left sides. Tilt control switch is located on the operator’s control panel.

- HIGH COLUMN: Column 6” longer than standard, providing increased vertical capacity to 28” at vertical position. High frame machines require a 16’ 4” blade.

- HIGH JAWS (JAWS ONLY): 10” high x 12” wide. In place of standard jaws provided with machine. Jaws use same clamping hardware provided with machine. Does not permit miter cutting.

- 45° HIGH JAWS (JAWS ONLY): In place of standard jaws provided with machine. One Front Jaw and one Rear Jaw, both mitered 45°, 10” high x 12” wide.

- MIST LUBE – MANUAL: Drop Lubrication System. (Requires compressed air connection 60-120psi)

- MIST LUBE – AUTOMATIC: Drop Lubrication System. (Requires compressed air connection 60-120psi)

- LASER ALIGNMENT LIGHT: Laser projector for quick spotting of the cut.

| Manufacturer | |

| SKU |

VT4555M

|

| Shipping Method |

LTL Freight

|

| Weight |

3,000 lb

|

| Dimensions |

101 × 73 × 89 in

|

| Country of Origin |

United States of America

|

| Warranty |

1 Year

|

There are currently no reviews for this product.

Be the first to review this product.

Looking for parts? Let us know what you need in the form, or give us a call at

281-241-9504