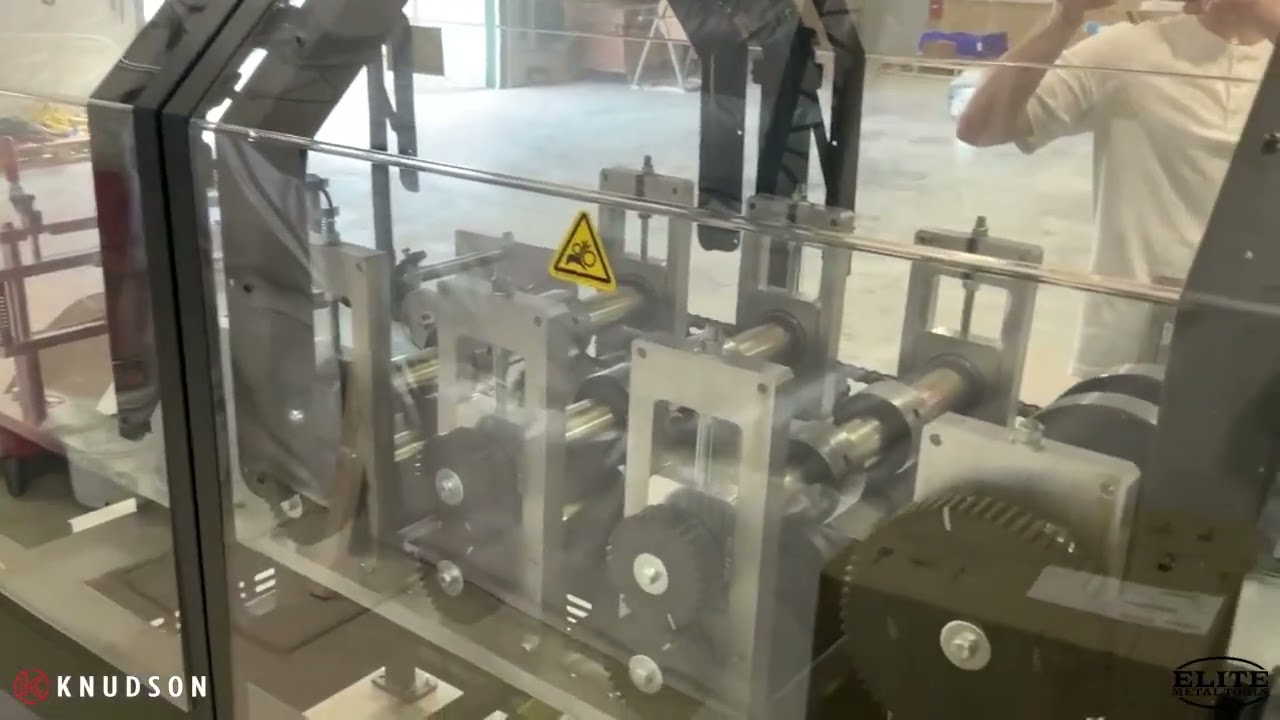

Knudson by Scottsdale Structural Framemaker Stud and Track Roll Forming Machine KFS 1420G1

| Manufacturer Part: | EMT ID: |

|

KFS1420G1

|

17065

|

- Stud/Track Web Sizes: 3 5/8 to 12-in. deep, Ga. 14 to Ga. 20 thick

- 5-station expandable manifold, printer mounting head, sheat/cut-off, 6,500-lb decoiler

- Flange dimpling tooling, 1.5x3.0-in. web service slot tooling

- Over 20 additional options, including control software, discounted Strucsoft MWF license, and much more.

Overview

The KFS-1420 FRAMEMAKER® showcases Knudson’s multi-profile/multi-thickness capabilities in a structural stud and track former. Out flagship model, the KFS-1420 forms C-Channel (stud) and U-Channel (track) light-gauge steel framing profiles for commercial and residential wall, floor, and truss construction.

Profile Specifications

KFS-1420 forms the following stud/track profiles:

- Stud/Track Web Sizes: 3 5/8 to 12-in. deep, Ga. 14 to Ga. 20 thick

- Stud Flange Sizes: 1.63, 2.00, 2.50-in

- Track Flange Sizes: 0.75-in (min) to 2.50-in (max)

- Oversized (standard) Track Profiles

- Profile Depth (max): 2.50-in

- Mechanical Change-Over – profile size and material thickness

Material Specifications

The KFS-1420 can successfully form the following materials.

- Material Thickness: 0.033 to 0.075-in (20 to 14 Ga)

- Material Strength: Grade 50 – up to 65-ksi Yield Strength

- Material Finish: Galvanized (up to G120), Painted, Bare

- Strip Width (min): 2.00-in

- Strip Width (max): 17.00-in

Production Speed Rates

- Running Line Speed: 120 feet per minute (max)

- Average Stud Production Rate (Actual Throughput): 50-ft/min

- Average Track Production Rate (Actual Throughput): 35-ft/min

Mechanical Specifications

Overall Dimensions

- Length: 192-in (16 ft)

- Width: 42.00-in

- Height: 66.00-in (including safety covers)

- Weight: 4,600-lbs

Roll-Forming Specifications

- 10 roll forming stations

- 1 Adjustment Stations

- 1 Pull-Out Station

- Exit-End Cut-Off

- Pass Line Height: 41.00-in

- Stop-to-Cut System

In-Line Tool Specifications

The KFS-1622 may be customized with a selection of in-line punch tools:

- A library of over 40 punch configurations

- Standard and Custom features available

Electrical Options Specifications

- 460 VAC / 60 Hz / 3 Ph – 48 Amps Full System Load

- 230 VAC / 60 Hz / 3 Ph – 97 Amps Full System Load

Control System Option Specifications

- Beck Automation SII Multi-Press Controller

- Stop-to-Cut/Punch Control Type

- Servo-Feed, Closed Loop Control

Drive System Specifications

- Running Line Speed: 120 feet per minute (max)

- 11 KW Servo Motor Drive

- Sprocket and Roller Chain Power Transfer – Power Take-Off and Station-to-Station

- Spur Gear Power Transfer – Bottom to Top

Hydraulic Power System Specifications

Hydraulic Power Specifications (punch tool operation/actuation):

- 7.5 HP Electric Motor

- Axial Piston Variable Displacement Pump (Pressure Compensated System)

- 5.5 gpm @ 2,000-psi

- 4-Way, 2-Position Valves for Tool Actuation

Environmental Specifications

- Ambient Air Temperature

- +41° to +131° Fahrenheit (+5° to +55° Celsius)

- Up to 24 hours at 122° Fahrenheit (50° Celsius)

- Humidity Range

- No Restrictions

- Altitude Range

- No Restrictions

- Vibration Shock and Bump

- Minimal vehicular transport on maintained roads

- Off-road transportation not recommended

- Transportation and Storage

- –13° to +131° Fahrenheit (–25° to +55° Celsius)

- Up to 24 hours at +158° Fahrenheit (+70° Celsius)

- Explosive Atmosphere

- Should not be operated in any kind of explosive atmosphere

- Airborne Noise Emissions

- Equivalent continuous A-weighted sound pressure level—less than 70 dB (A)

Fluid Specifications

The factory recommends use of the following fluids with the KFS-35X Power Pack:

- Hydraulic Oil – ISO 46 Oil

- Coolant – Soluble Oil EP CF

- Blade/Punch Lubricant –WD-40

- Shaft Lube – Mobile Synthetic Lubricating Grease

Options

- Material Handling

- Dead-Roller Conveyor Tables for Material Discharge

- Coil Handling

- Motorized Stock Reels (Uncoilers) for Coil Feed

- Powered Material Straighteners/Levelers for Coil Straightness

- Software

- Connex™ Web-Based Enterprise Software

- Network Connection to Machinery

- Production Planning and Job Programming/Scheduling

- Inventory Management and Production Reporting

- CAD/Building Design Software Compatibility

- Strucsoft Solutions – MWF Pro Metal

- Vertex Systems - Vertex BD

- Arktec – TriCalc

- Connex™ Web-Based Enterprise Software

| Manufacturer | |

| SKU |

KFS1420G1

|

| Shipping Method |

Flatbed

|

| Weight |

4,600 lb

|

| Dimensions |

192 × 42 × 66 in

|

| Country of Origin |

United States of America

|

| Warranty |

1 Year

|