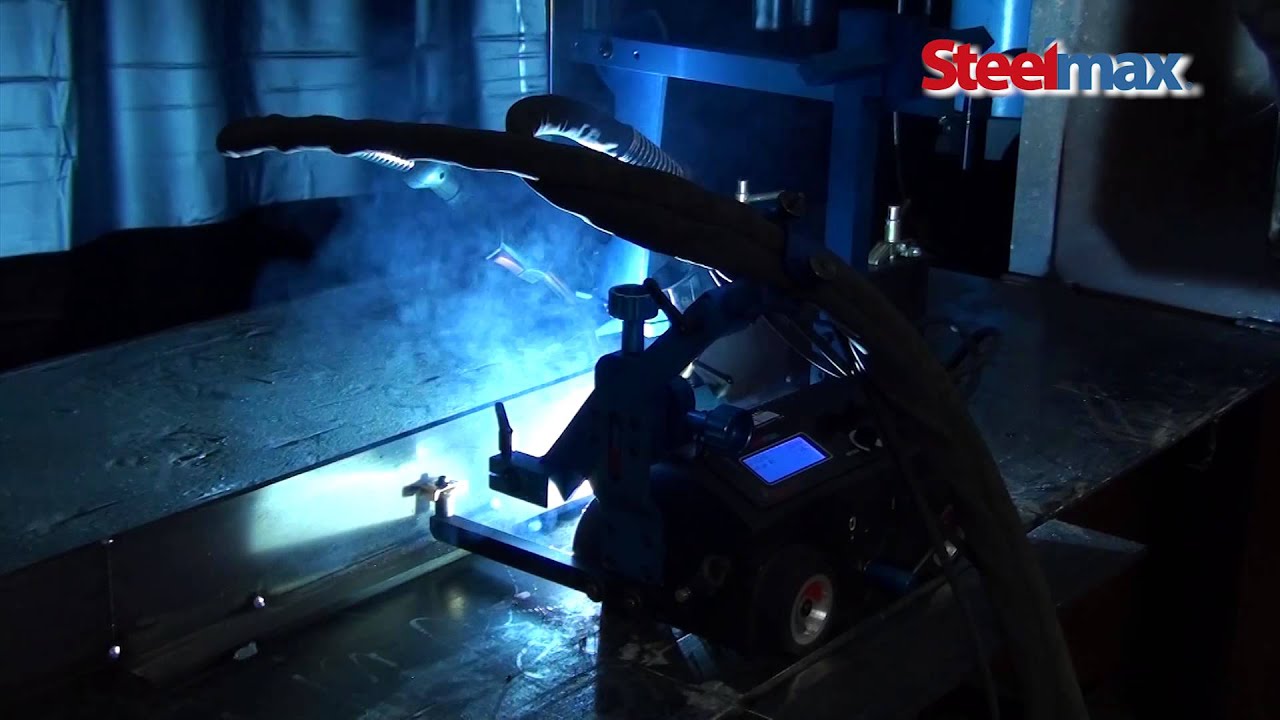

Steelmax Arc Runner 115V Single Phase Portable Programmable Welding Carriage SM-WC-AR

| Manufacturer Part: | EMT ID: |

|

SM-WC-AR

|

19103

|

- Welding Positions: Vertical/Horizontal

- Chassis to material clearance: 3/16” minimum

- Guide roller adjustment: 3”

- Torch adjustment (up-down, left-right): 1-3/8”

Description

The Steelmax Arc Runner is a portable, programmable welding carriage designed to produce consistent, high-quality welds. The powerful magnetic base and closed loop electronic speed control provide speed stabilization in all positions. The unit enables weld bead geometry that is exact to the required specifications, substantially reducing costly over welding and decreasing filler metal usage.

The Arc Runner can be programmed in continuous or stitch welding modes. Two easy-to-use function buttons enable programming of weld length, distance between welds, reverse fill, crater fill time, and other required patters and parameters. The Arc Runner travels at full speed between stitches, which saves valuable welding time.

Arc Runner’s micro processor allows for development, storage, and reproduction of up to 40 different welding programs for various joint configurations and multi-pass, multi-layer welds. Once an optimum weld procedure is developed, stored and programmed, Arc Runner will repeat it over and over again.

Features

- Compact, lightweight design with durable cast aluminum housing

- Permanent magnet clamping system with on/off lever ensures positive magnetic traction

- Maintenance free, 4-wheel planetary gear drive system

- Standard torch holder for welding torches with diameters of 5/8” – 7/8”

- Precise cross-slide torch adjustment

- Multifunctional LED display and 2 function buttons for welding pattern programming

- Closed-loop speed control system stabilizes travel speed to reduce weld defects and costly repair work

- Consistent heat input reduces distortion

- Automatic ARC ON/OFF system initiates welding and travel, simultaneously

- Self-guiding roller arms eliminate the need for track

- Improves work environment – reduces fatigue and repetitive stress – removes operator from heat and fumes

- Capable of carrying and controlling 2 torches (without oscillation)

- Up to 40 complete programs may be stored in non-volatile memory

Specifications

- Power Supply: 115V Single Phase

- Welding Positions: Vertical/Horizontal

- Chassis to material clearance: 3/16” minimum

- Drive System

- Friction drive with worm gear reduction

- Four wheel drive, heat, resistant silicone wheels

- Tracking method: 2 roller guides in various configurations

- Towing force

- Vertical: 33.7 ft.lbs

- Horizontal: 49.5 ft.lbs

- Torch Adjustment

- Up-Down: 1-3/8”

- Left-Right: 1-3/8”

- Guide roller adjustment: 3”

- Control Panel

- Travel Direction Switch: program start, direction left/stop/program start, direction right

- Function button F1: continuous welding, dash, crater fill, backweld

- Function button F2: Value change “+” or “-“

- Arc ignition switch: TEST / 0 / I

- Speed knob

- Horizontal speed: 0 – 47¼” /min

- Vertical speed: 0 – 43-3/8” /min

- Automatic stop: Limit switches at both ends

- Noise level: < 70 dB

- Dimensions (LxWxH): 15” x 14-5/8” x 15-3/8”

- Weight: 29.8 lbs

Optional Accessories

- Pendulum torch oscillator

- Dual Torch Mount

- Torch Extension Arm

- Edge Following Guide Arms

- Adjustable Guide Arms

- Flexible Guide Rail

- Flexible Guide Rail Alignment Tool

- Rail Guide Arms for Arc Runner

- Magnet for Flex Rail

- Quick Connect Torch Holder

- Magnet Guide Arms for Arc Runner

- Low Guide Arms for Arc Runner

- High Guide Arms for Arc Runner

| Manufacturer | |

| SKU |

SM-WC-AR

|

| UPC |

848118005131

|

| Shipping Method |

Ground

|

| Weight |

40 lb

|

| Dimensions |

19 × 16 × 16 in

|

| Country of Origin |

Poland

|