Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

Which Ironworker is Right for You?

About Ironworkers

Ironworkers are the “Swiss Army Knife” of metalworking and metal fabrication shops. Utilizing mechanical advantages such as hydraulics, the ironworker is capable of shearing, punching, notching, and bending, as well as an assortment of other forming actions. The main mechanic of these machines is similar to that of a hydraulic press Since the ironworker machine is essentially multiple machines in one, it is difficult to pinpoint when it was invented. Though some say the concept was being implemented in the early 1800s, others argue it wasn’t until the 1940s that the ironworker was invented. Regardless, in the 1960s patents were acquired and mass manufacturing of ironworker machines began in the US.

Though most ironworkers rank similarly in versatility, when purchasing one for your shop or business it is encouraged to be very thorough when selecting the right machine. Finding the right ironworker for your applications will save time, energy, and in the long run, money. The most important things to consider when selecting an ironworker are its applications, capacity, and versatility.

Applications

Before diving into different machine styles, brands, prices, etc. it is important to lay out a list of how you will utilize an ironworker. The ironworker machine is ideal for short-run projects that require many different metalworking processes—bending, shearing, punching, etc. Most ironworkers come standard with 3 workstations, but can have as many as 5 on larger machines. These stations utilize the hydraulic force to drive specific tooling for punching, notching, pipe notching, flat bar shearing, angle shearing, bar shearing, forming processes, and bending. Knowing how you will use your ironworker will better determine how many stations you need and what you need your stations to do. All manufactures provide different options for their ironworkers, as well as different standard equipment; additional upgrades can be added to your machine depending on the machine.

Capacity

Ironworkers are generally rated by tonnage according to the punch station, which is standard on most ironworkers. Punching typically requires more tonnage than other functions of an ironworker. The rule of thumb for most metal (shear strength between 0.345 and 0.483 kN/mm2) is as follows:

40-ton ironworkers punch 1-inch rounds in ½-inch material.

60-ton ironworkers punch 1-inch rounds in ¾-inch material.

80-ton ironworkers punch 1-inch rounds in 1-inch material.

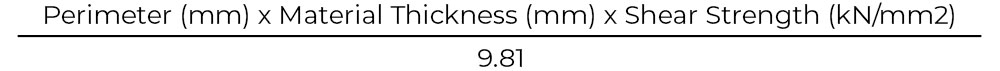

Though this is a good rule of thumb to follow when choosing an ironworker for your shop, we recommend determining the exact tonnage needs for your applications. The required tonnage to punch material (or the punching force) varies depending on three factors: perimeter of the punch, shear strength of the material, and material thickness. The tonnage can be calculated with the following equation:

The perimeter of the punch is calculated according to the shape and for this calculation should be measured in millimeters (mm).

| Shape | Formula | Variables (p = Perimeter) |

| Circle |

d is the diameter |

|

| Triangle |

a, b, and c are the lengths of the sides of the triangle |

|

| Square |

a is the side length |

|

| Rectangle |

l is the length, w is the width |

|

| Equilateral Polygon |

n is the number of sides, a is the length of one side |

|

| Regular Polygon |

n is the number of sides, b is the distance between the center of the polygon and a vertex |

|

| General Polygon |

ai is the length of the i-th (1st 2nd 3rd ... nth) side of an n-sided polygon |

Shear strength is a measurement of the force needed to produce a sliding failure on the material along a parallel plane to the direction of the force; punching a hole in paper is an example of paper failing in shear. Shear strength is commonly measured in kilonewtons per square millimeter (kN/mm2) or pounds per square inch (PSI). All materials shear fail at different levels of force, so it is important to understand the specifications of the material you are working with. The material specifications also include the thickness of the material being handled.

Versatility

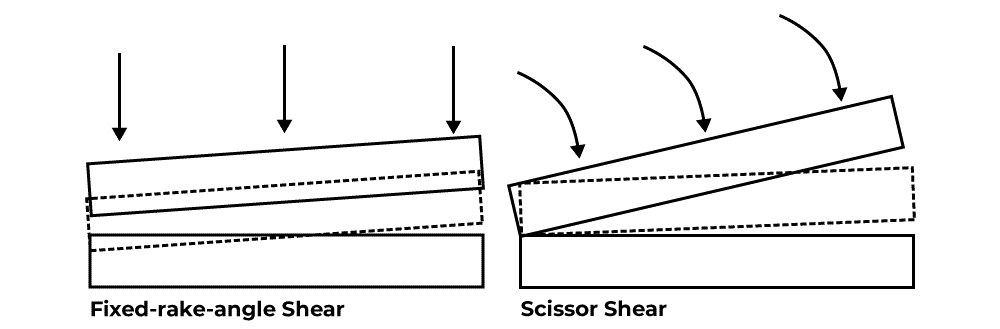

There are two types of shearing methods offered in ironworker machines. Why is it important to know the distinction? In the majority of brands, all tool stations are driven through the action of the shear. The shear station is arguably the most utilized, and important station on an ironworker, and there are considerations to be made regarding how it operates.

Fixed-rake-angle shears maintain a consistent angle through the entirety of the cutting action. The movement of this type of shear is always vertical and provides the same tonnage at every point within the shear; this means the capacity is always the same. The angle also remains constant throughout the cut. Scissor hears pivot on one side of the machine and have a hinged movement, changing the angle as the shear blade lowers. This us useful when different rake angles are desired for different materials. For example, positioning thicker material closer to the pivot will provide a larger rack angle, thinner material can be positioned further from the pivot point for a smaller rack angle. Repositioning material within a scissor shear also reduces distortion, which cannot be done on a fixed-rake-angle shear.

Ironworkers are incredibly versatile machines, able to perform a variety of metalworking processes that are incredibly common in any metal fabrication operation. With many different options in manufacture, tonnage, standard options, and add-ons, as well as the small footprint required, ironworkers are the one of the most useful assets for a metal shop.

Choosing the perfect ironworker is an important task for your shop or business. We at Elite Metal Tools understand the importance of buying the right machine and are committed to providing you with the best information, prices, and buying experience. We carry the web’s largest selection of industry-leading ironworkers competitive prices and, as always, Free Shipping!