Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

What to Consider when Choosing a Hydraulic Press

About Hydraulic Presses

The use of hydraulic presses over the traditional mechanical press has increased dramatically over the last 30 years. Until recent history, the mechanical press was the common machine for production press work. The mechanical press utilizes a rack and pinion as well as a crankshaft to achieve significant tonnage without an external power source. It wasn’t until the early 1990s that hydraulic presses became the more popular option.

Hydraulic Presses utilize hydraulic cylinders, single-direction mechanic actuators, to create compressive force. Invented in 1795 by Joseph Bramah, hydraulic systems were conceptualized by studying the movement of fluids through early toilets, which were later replaced by toilets created by Bramah.

Hydraulics depend on Pascal's law, which basically states that when an incompressible fluid is given pressure, the pressure is applied evenly in every direction. This law allows the force generated from compressing a fluid to be utilized in moving mechanics like a piston. It was also discovered that using a smaller piston to pressurize the fluid, through which moves a larger piston, generates greater forces than using two equally-sized pistons. This is called a force multiplier and is crucial when creating a hydraulic system.

Needs

Before seeking out the best prices, you should consider the role a hydraulic press will have in your personal shop or business. Writing a full list of tasks you’d like a press to accomplish can provide a better scope of the strength, size, type, model, etc. of press you will need. Be sure to understand what a hydraulic press can do; the range of abilities are extensive. Bending, blanking, drawing, forming, molding, punching, and stamping are just some of abilities of hydraulic presses. Not all machines are capable of these actions and should be taken into consideration.

Tonnage

After considering the uses for your press, the next important question to ask is what tonnage will be required for the jobs. If you are switching from a mechanical press to a hydraulic press, the tonnage requirements will not change. Do consider, however, when choosing the right hydraulic press, you only need to know the maximum tonnage you will require for any given job. Opposed to a mechanical press, most hydraulic presses can be tuned down to a lower tonnage depending on the task.

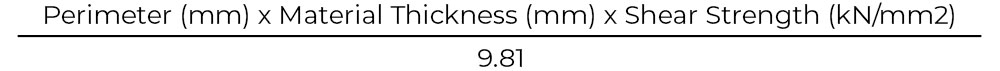

The required tonnage to punch material (or the punching force) varies depending on three factors: perimeter of the punch, shear strength of the material, and material thickness. The tonnage can be calculated with the following equation:

Shear strength is a measurement of the force needed to produce a sliding failure on the material along a parallel plane to the direction of the force; punching a hole in paper is an example of paper failing in shear. Shear strength is commonly measured in kilonewtons per square millimeter (kN/mm2) or pounds per square inch (PSI). All materials shear fail at different levels of force, so it is important to understand the specifications of the material you are working with. The material specifications also include the thickness of the material being handled.

Though punching is a common use for a hydraulic press, other functions also require specific tonnage in order to be effective. It is encouraged to understand the tonnage requirements for any job you plan to utilize a hydraulic press for.

Press Type

After narrowing down a press’s uses and the required tonnage, you can begin to explore the type of press that is suited for the tasks. There are numerous types of hydraulic presses, each are made for different tasks, and some made to complete multiple tasks. The two main categories of hydraulic presses are C-Frame Presses and H-Frame Presses. These two presses are the most used presses in the metalworking industry due to their versatility.

C-Frame Presses—also known as open frame or gap frame presses—are space-efficient machines with three-sided access. They are utilized mainly by manufacturing operations due to their ability to preform large amounts of work while taking up minimal space comparted to other presses. Because of its smaller size, the C-Frame does sacrifice power and the ability to work larger pieces. The C-Frame press is ideal for shops in need of a versatile press capable of the common press functions.

H-Frame Presses—also known as 4 post presses or 4 column presses— are much larger than C-Frame presses and generally more powerful. These presses, as their name suggests, commonly have four posts that guide the pressing plate to the table and tooling. Though some have two guiding posts, the H-Press is known to have better accuracy and power due to its symmetry. Unlike some C-Frame presses, when using a high tonnage, the pressure is evenly distributed and the machine will not “yawn”. The H-Frame presses are suitable for shops and businesses in need of a powerful press capable of nearly all press functions.

Accessories and Tooling

Most modern hydraulic presses come standard with many features such as dwell timers, automatic cycling, distance reversal limit switches, and light curtains. However, some presses come equipped with a wide variety of additional controls and features that can greatly improve the productivity and usability of the machine. Choosing a more equipped machine is a more expensive investment, however it may save you or your business time and money in the long run.

Whether you are purchasing a replacement hydraulic press or your first, it is important to consider the tooling style you will be using. If you already have tooling, be sure to find out if your tooling will match your press style. If you are purchasing a new press with new tooling, check the specifications of both to ensure you will have the best results.

Choosing the perfect hydraulic press is an important task for your shop or business. We at Elite Metal Tools understand the importance of buying the right machine and are committed to providing you with the best information, prices, and experience. We have a huge variety of industry-leading hydraulic presses and other machinery at competitive prices and, as always, Free Shipping!