Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

Tin Knocker Pittsburgh Machines: Capabilities & Buying Guide

What Is a Pittsburgh Machine?

A Pittsburgh machine, also called a lockformer or Pitts machine, is a roll-forming machine used in HVAC sheet-metal fabrication. Its primary role is to create the seams and edges that allow rectangular ductwork to lock together quickly and securely. By forming precise profiles—both female and male—these machines make it possible to build airtight duct systems without relying on welding or excessive fastening.

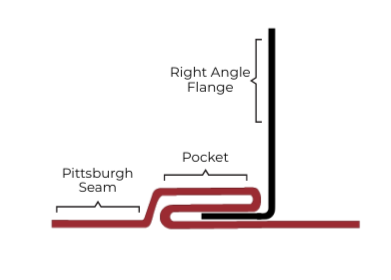

The result of this process is the Pittsburgh lock: the completed joint created when the female Pittsburgh (Pittsburgh seam) and a corresponding male Pittsburgh (right angle flange) interlock.

The Main Profiles Pittsburgh Machines Can Make

1. Pittsburgh Seam

(Also called Female Pittsburgh)

The most common profile, the Pittsburgh seam is a recessed, folded edge that receives a mating male profile. It is the backbone of rectangular duct fabrication, providing strength and air-tightness once locked closed.

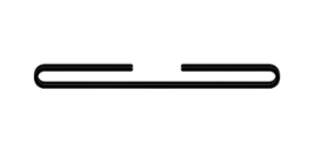

2. Drive Cleat

A straight male edge that locks into a female Pittsburgh seam. Drive cleats are widely used in rectangular duct connections, offering a simple, strong, and quick-to-assemble joint.

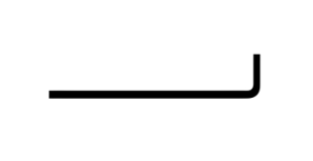

3. Right-Angle Flange

(Also called Male Pittsburgh or Flange Roll)

This profile creates a 90° flange on the edge of sheet metal. It’s frequently used for frames, access doors, and mating duct edges, giving fabricators versatility beyond standard seams.

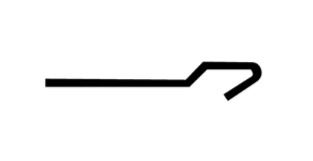

4. Acme Lock

(Also called Double Seam Rolls)

The Acme lock is a more compact, interlocking male edge. It’s useful for fittings and space-constrained sections where a drive cleat may not fit, while still providing a strong connection.

Tin Knocker Pittsburgh Machines and Their Capabilities

Tin Knocker offers a range of Pittsburgh machines designed to handle different gauges and profile needs. Let’s look at three of their featured models:

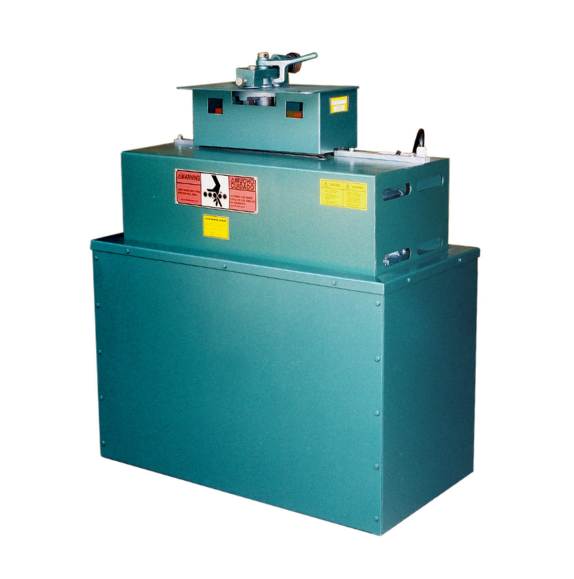

TK 24-Ga Pittsburgh with Stand

- Gauge range: Up to 24 gauge mild steel

- Female profile: Pittsburgh seam

- Other profiles: Right-angle flange available with optional flanging attachment

- Best for: Light shop work, small projects, or field use

This compact machine is perfect for lighter materials and smaller shops. Adding the optional flanging attachment expands its use by allowing quick, uniform flanges on sheet edges.

TK 24-Ga Pittsburgh with Stand & Flange Attachment

- Gauge range: Up to 24 gauge mild steel

- Female profile: Pittsburgh seam

- Other profiles: Right-angle flange (included via built-in flanger)

- Best for: Fabricators who need flanging capability right out of the box

This version ships with the flanging attachment installed, saving time and expanding capability without requiring an upgrade later.

TK 20-Ga Pittsburgh (Drive Cleat or Acme Rolls)

- Gauge range: 20–26 gauge mild steel

- Female profile: Pittsburgh seam

- Other profiles: Choice of Drive Cleat or Acme Lock rolls; Right-angle flange available as an option

- Best for: Shops running higher-volume production in 20–26 gauge material

This model offers flexibility by letting you choose your preferred outboard roll set. Whether your shop works primarily with drive cleats or relies on compact Acme locks, this machine adapts. An optional flanging setup adds even more versatility.

Comparison at a Glance

| Model | Material Gauge | Female Profile | Male / Other Profiles |

|---|---|---|---|

| TK 24-Ga w/ Stand | 24-ga & lighter | Pittsburgh seam | Right-angle flange (optional) |

| TK 24-Ga w/ Stand & Flanger | 24-ga & lighter | Pittsburgh seam | Right-angle flange (included) |

| TK 20-Ga (Drive Cleat or Acme) | 20–26 ga | Pittsburgh seam | Drive Cleat or Acme; Right-angle flange (optional) |

Choosing the Right Machine

- For light material and portability: The TK 24-ga Pittsburgh with Stand is a strong choice. Add the flanger if you need flange capability.

- For built-in flanging convenience: The TK 24-ga with Flanging Attachment gives you two key profiles from day one.

- For heavier shop production and profile flexibility: The TK 20-ga model covers a wider gauge range and lets you pick the male profile that fits your workflow best.

Conclusion

Understanding the profiles a Pittsburgh machine can produce is key to selecting the right equipment for your HVAC shop. Whether you need the classic Pittsburgh seam, a Drive Cleat, a Right-Angle Flange, or the compact Acme Lock, Tin Knocker has a model tailored to your needs. From portable 24-ga machines to the more versatile 20-ga workhorse, these machines help fabricators build ductwork faster, stronger, and more efficiently.