Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

Swenson Shear: Exposed Fastener Shears & How to Choose One

Swenson Shear manufactures some of the highest quality metal roofing tools on the market. Known for their ease of use and customization, they stand out as a leader in the industry. Their on-site metal roofing tools are made to meet your specific needs – here we will walk through what you need to know before you buy.

Exposed Fastener Roofing

By definition, an exposed fastener metal roof system is one in which the metal panels are fastened directly to the structure by fasteners which are left visible to the eye. Affordable and easy to install, exposed fastener roofs frequently use corrugated metal and, when cut and installed properly, can be very attractive, also. Exposed fastener roofs frequently appear on agricultural and industrial structures, but they are often used on residential buildings, as well.

While a bit more cost and labor-intensive than exposed fastener roofing, standing seam roofs offer the following advantages:

- Durability: Since the fasteners are most vulnerable to wear and weathering, covering them helps make the roof hold up better against the elements.

- Variety of styles: Standing seam roofs accommodate a variety of colors, panel sizes/shapes and seam styles.

- Curb appeal: Standing seam metal roofs are increasing in popularity for their sleek, modern appearance.

- Low maintenance: Metal roofs, in general, are among the easiest roofs to maintain, and standing seam roofs even more so.

Why use a shear?

There are many different options for resizing and reshaping sheet metal roofing. While some roofing contractors are considering nibblers, shears such as Swenson’s offering, have proven to be the better option for sheet metal roofing. Speed, precision, and kerf are all factors that play into this decision. Speed and precision tend to be mutually exclusive when choosing on-site roofing equipment. While a nibbler or power shears have the ability to move through material faster, it is at the cost of precision. Whereas the straight-blade Swenson shears are accurate and foolproof. Though speed may be sacrificed for an inexperienced operator, an experienced roofer will lose little time operating a shear. Kerf is the material removed in the cutting process. Nibblers remove material in order to resize and reshape sheet metal. Shears, however, do not remove metal within their process. Not only does this make measurements more accurate, but shears do not create a mess.

How to Choose the Right Shear

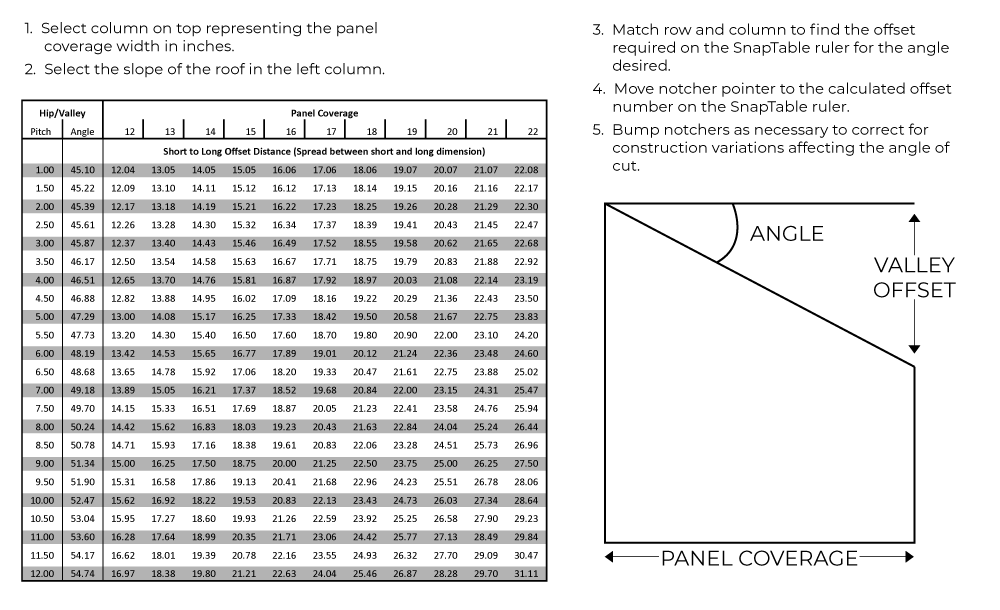

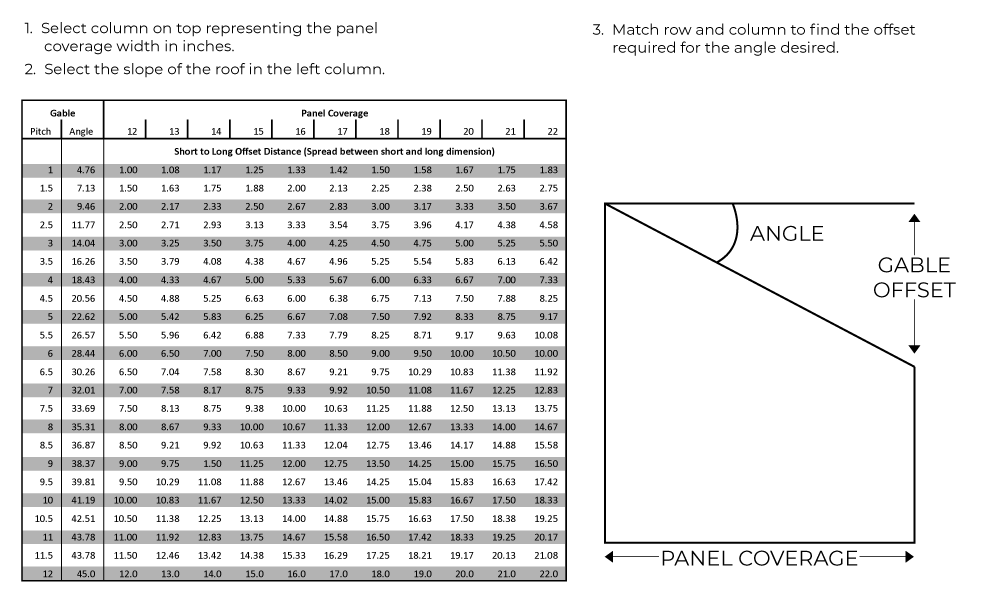

When selecting a shear, there are some considerations to be made. What is your application? If you are only cutting material to length/doing straight cuts, the M42 – Straight Cut Shear would best suit your needs as it is designed specifically for straight cuts and not gables, valleys, or auxiliary cutting. If cutting only gables, your best solution is the M48 - Heavy Duty Pivot Shear. Ideal for cutting exposed fastener panels up to 48″ in width, the pivot shear can produce straight cuts at 90 degrees or up to an 8/12 gable. When cutting for valleys, the M64 – Hip/Valley shear will accommodate your application. The Hip and Valley Roofing Shear can make straight line cuts at 90 degrees up to a 2/12 gable, and can accommodate up to a 9/12 valley on metal panels up to 64 inches in length. The best solution for cutting BOTH Valleys and Gables is the Hip/Valley Shear, specifically for its versatility in these specific cuts. For auxiliary cuts, Swenson offers a Soffit Siding Shear, ideal for cutting siding, metal shingles or soffit to length.

Every Swenson Shear is shipped with a custom blade. This blade is profiled to the specific roofing specifications from metal roofing manufacturers as well as for your application. For example, the M48 - Heavy Duty Pivot Shear comes with a blade specific to your manufacturer, panel profile, and desired pitch. 80% of the metal roofing market uses some type of Ag panel profile. An Ag panel profile is 9 inches on center. However, each manufacturer's version has a different name and MUST be provided upon ordering.

**When purchasing a Swenson Shear, either online or over the phone, you must specify the panel manufacturer, panel profile, and gable/valley pitch.**

Examples:

- Heavy Duty Pivot Shear M48

- Manufacturer: Central States Manufacturing Ag Panel

- Profile: Panel Loc Plus

- Pitch: 4/12 Gable (cuts 3/12 - 5/12 Gable)

- Hip/Valley Roofing Shear M64

- Manufacturer: Metal Sales Manufacturing

- Profile: Pro-Panel II

- Pitch: 6/12 Valley