Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

Lets Learn About - Band Saw Blades

The Lets Learn About Series is an excercise in which we try to anticipate the most common questions as they relate to the purchase of machinery and accompany them with the answers. If you have a question that you think would be a good fit please contact us.

Types of Band Saw Blades

Band saw blades come in various types, each designed for specific cutting applications. Understanding the differences between them is crucial for achieving optimal results. Let's explore the most common types:

- Carbon Steel Blades: Known for their affordability and versatility, carbon steel blades are suitable for general-purpose cutting tasks. They are ideal for cutting wood, non-ferrous metals, and plastics.

- Bi-Metal Blades: These blades combine the durability of high-speed steel (HSS) teeth with the flexibility of a spring steel back. Bi-metal blades are well-suited for cutting through a wide range of materials, including ferrous metals, stainless steel, and alloys.

- Carbide-Tipped Blades: With their tungsten carbide teeth, these blades are highly durable and suitable for cutting abrasive materials like hardwoods, exotic woods, and laminates. They maintain their sharpness even when exposed to demanding cutting conditions.

- Diamond Blades: Used primarily for cutting hard materials like glass, ceramics, and stone, diamond blades feature a diamond-coated edge for exceptional cutting performance. They are commonly used in specialized applications such as tile work and masonry.

Blade Selection Guide

Choosing the right band saw blade for your specific cutting task is essential for achieving optimal results. Consider the following factors when making your selection:

- Material Type: Different materials require different blade characteristics. Determine whether you're cutting wood, metal, plastics, or other materials, and choose a blade that is specifically designed for that material.

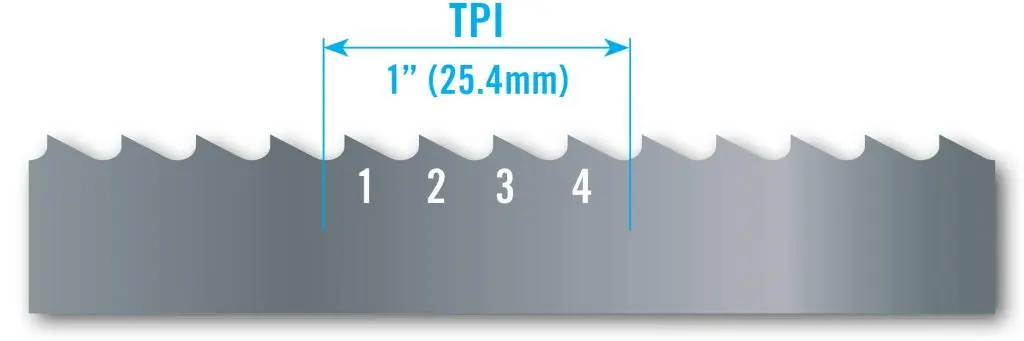

- Thickness: The thickness of the material being cut influences blade selection. Thicker materials require blades with fewer teeth per inch (TPI) for efficient cutting, while thinner materials benefit from blades with a higher TPI for smoother cuts.

- Tooth Pitch: The tooth pitch, or the distance between teeth, impacts cutting speed and chip removal. Coarse tooth pitches are ideal for faster cutting through thicker materials, while fine tooth pitches provide smoother cuts in thinner materials.

- Blade Width: The width of the blade affects cutting accuracy and stability. Thicker blades are better suited for straight cuts and resawing, while thinner blades excel in intricate curves and tight radius cuts.

Blade Maintenance and Care

Proper maintenance and care are vital for extending the life of your band saw blades and ensuring optimal performance. Follow these guidelines:

- Cleaning: Regularly clean the blade to remove pitch, debris, and contaminants. Use a blade-cleaning solution or a mixture of water and mild detergent. Scrub gently with a nylon brush, rinse, and dry thoroughly before storage.

- Lubrication: Apply a lubricant specifically designed for band saw blades to reduce friction and prolong blade life. Follow the manufacturer's recommendations for the appropriate lubricant and application method.

- Storage: Store your band saw blades in a dry and clean environment, away from moisture and extreme temperatures. Consider using blade protectors or storage cases to prevent damage or accidental contact.

- Blade Sharpening: Dull blades can lead to poor cutting performance and increased strain on the machine. Learn proper blade sharpening techniques or seek professional sharpening services to maintain a sharp cutting edge.

Blade Safety Precautions

Working with band saw blades requires strict adherence to safety precautions to prevent accidents and injuries. Prioritize the following safety measures:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses or goggles, hearing protection, and gloves. Avoid loose clothing or jewelry that may get caught in the blade.

- Machine Setup: Follow the manufacturer's instructions for setting up the band saw machine correctly. Ensure the blade is properly tensioned, the guides are aligned, and the blade tracking is adjusted for smooth operation.

- Safe Operating Techniques:

- Maintain a secure grip and control of the workpiece while feeding it into the blade.

- Keep your hands at a safe distance from the blade, using push sticks or other devices to guide the material through the cut.

- Avoid forcing or bending the blade during cutting, as it can lead to blade damage or breakage.

- Never leave the band saw unattended while it's running.

- Blade Changes: When replacing or changing blades, ensure the machine is powered off and unplugged. Follow proper procedures for blade installation, including adjusting tension and tracking.

Troubleshooting Common Blade Issues

Even with proper care, band saw blades may encounter issues. Here are some common problems and their potential solutions:

- Blade Breakage: Excessive feed pressure, incorrect blade tension, or using an inappropriate blade for the material can cause blade breakage. Check for proper tension, use the correct blade for the task, and adjust the feed rate accordingly.

- Tracking Issues: If the blade is not tracking correctly on the wheels, it can result in uneven cuts and premature blade wear. Check the blade guides and adjust the tracking knob to ensure the blade runs smoothly and centrally on the wheels.

- Dullness: Dull blades lead to inefficient cutting and can cause burning or tearing of the material. Regularly inspect the blade for signs of dullness and sharpen or replace it as needed.https://www.elitemetaltools.com/tool-shop/products/jet-bi-metal-bandsaw-blade-1-x-0035-x-132-1/2-4/6t-ehb-1018v-891096?sku=JT9-891096

Summary

In conclusion, band saw blades are crucial tools for achieving precise cuts in various materials. Understanding the different types of blades, selecting the right one for the task, and properly maintaining and operating them are key to maximizing their performance and lifespan. Remember to prioritize safety by using appropriate PPE, following machine setup guidelines, and adopting safe operating techniques. By troubleshooting common issues and taking proactive measures, you can ensure a smooth cutting experience with your band saw blades.

With this ultimate guide, you now have the knowledge to confidently choose, maintain, and operate band saw blades. Harness the potential of these versatile tools and elevate your cutting capabilities in woodworking, metalworking, and beyond.

Conclusion

Band saw blades play a vital role in achieving precise and efficient cuts. By understanding the various types of blades, considering important selection factors, and implementing proper maintenance and safety measures, you can optimize your band saw blade usage. With this comprehensive guide, you are equipped with the knowledge and insights to make informed decisions, prolong the life of your blades, and work safely. Embrace the world of band saw blades and elevate your cutting projects to new heights.