Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

Jointing & Planing: 101

Precision is arguably the most important aspect of woodworking—a great work of craftsmanship can be ruined by only a couple millimeters. Luckily for us, there are tools specifically made to accurately size, shape, and level workpieces and eliminate deformities. Two such tools are jointers and planers.

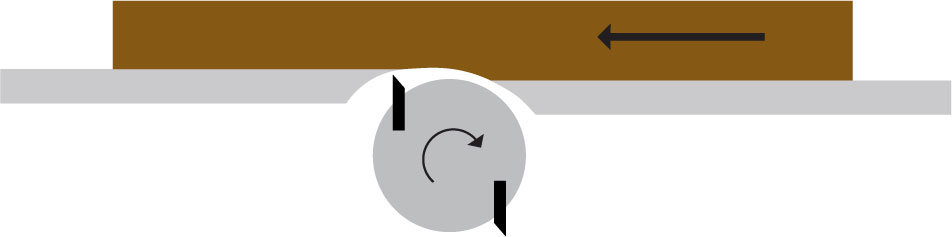

Planers, or thickness planers, have different useful functions. Primarily, they are used to smooth a roughly cut piece of material. When the face of a board, beam, etc. is unable to be effectively smoothed by sanding a planer is your best option. Another function of a planer is to create a uniform thickness along the length of a board. Planers are pre-set to a desired thickness allowing the user to plane multiple boards to the same thickness.

For commercial or industrial applications, larger more powerful units are far more desirable. There is a far wider range of options when choosing between commercial-grade planers. Such machines can range between $1,500 and $60,000 depending on factors such as single vs. double surface planning, programmable settings, digital readouts, automatic feed systems, etc. Beyond these more high-end features, commercial planers operate very similarly. Motor strength can range from 5 to 15 HP—a higher HP motor can ensure clean cuts on denser materials. Table size is also much larger than benchtop models, ranging between 15” and 35” wide and up to 50” deep. The cutting depth varies greatly among commercial models, it also varies depending on the width of the workpiece being cut. Higher HP machines can cut material up to ¼” deep. But with materials at maximum width are cut at a depth of 1/16” to 1/8”. Some machines use a metric called “cuts per minute” (CPM). This is a metric that combines the RPM of the cutter head and the blades on the cutter head. This metric is useful, however, cutter heads can be changed to increase your CPM. A more important metric is RPM of the cutter head—matching a cutter head to your application is more useful than getting a machine and head with a high CPM. Cutting heads in commercial units have either a traditional multi-knife system or helical head system. Both have advantages and disadvantages given your application, and are addressed at length in another article, here. It is worth noting that there are alternatives when working with very large or wide boards. Newer wide belt sanding or drum sanding machines are very capable when attempting to take thickness off of a board. These are a much more expensive and time-consuming option, but may be more effective for particular applications.

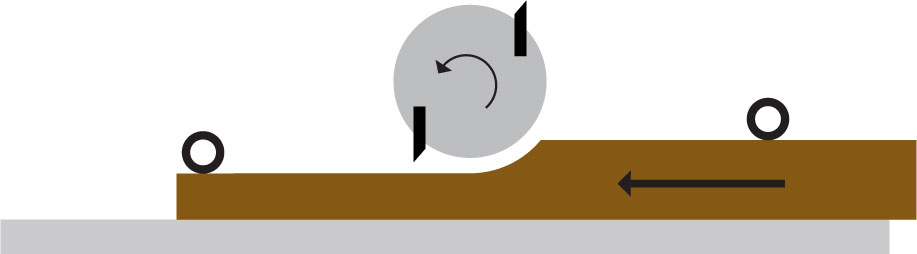

Though they operate similarly, jointers and planers provide very different functions. Planers create a uniform thickness by setting the cutter head and the table a certain distance apart. However, finding a perfect workpiece, with no cups, bows, twists, and crooks, is nearly impossible. Running such a piece through a planer will not create a clean, uniform thickness. The function of a jointer is to create a smooth, flat face on one side of a workpiece—not necessarily to change the thickness of a board.

When processing your board, the first step should always be jointing. Creating an even, flat surface is crucial to effectively plane the material. Like planers, jointers come in both benchtop models and commercial models. Benchtop models are effective and portable, however, not able to handle larger or denser pieces of material. Benchtop jointers run on motors around 1 HP and can cut at widths no greater than about 6”. Jointers as a whole are capable of cutting at greater depths than planers due to their design and purpose, and benchtop models rarely exceed 1/8” cutting depth. Standard jointers, or commercial-grade jointers are freestanding and have long tables. These jointers generally cut between 8” and 20”, but there are some large industrial models that cut up to 60”. Horsepower in standard commercial jointers normally ranges between 1 and 8 HP. And some can cut at depths up to 3/8” depending on your material width. It is always recommended to take multiple passes at smaller depths to reduce wear on your machine as well as chipping, chatter, etc.

The third, and most practical machine option is a jointer/planer combination machine. This machine completes the functions of both a jointer and a planer, and utilizes the same amount of space as a commercial jointer. The jointer/planer combination machine makes the most sense for shops or businesses who build custom furniture, cabinetry, or need to resize boards often for their application. Sine most workpieces require jointing in order to plane, a combination machine is a very practical machine to add to your shop.