Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

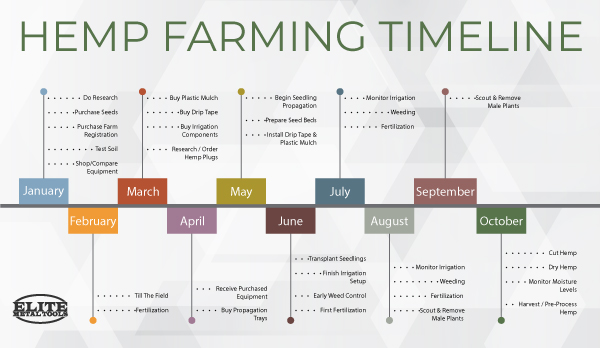

Hemp Farming Timeline & Budget

In 2018, the Farm Bill federally allowed the growing of hemp for hemp-derived products including supplements, textiles, food products, and commercial materials. Utilizing unique attributes of different cannabis species, industrial farming and processing has created the opportunity to create new products, improve existing products, and create a more sustainable model for the future. This young industry continues to grow, and with that growth comes many questions about best practices, economic sustainability, and longevity of the production, processing, and use of hemp. We at Elite Metal Tools are invested in laying the groundwork for an industry that can create sustainability in the industrial world.

As farmers of a relatively new product, understanding the plant is the first step. The Cannabaceae family of flowering plants include Cannabis (hemp), Humulus (hops), and Celtis (hackberries). Though there are over 170 sub-species within the family, hops and hemp are the only economically and industrially useful plants. Hemp is considered an erect-standing herb unlike its cousins, hops and hackberries. Hemp is often dioecious, meaning there are both masculine and feminine variants of the crop. Opposed to monoecious crops (act as both masculine and feminine), which are self-pollinating, dioecious crops such as hemp require cross pollination via wind or insects. The masculine variant is far different than the feminine variant, bearing larger flowers and growing taller. However, masculine plants die quickly after pollination whereas feminine plants grow to full maturity. Feminine variants are often the only harvestable plant when growing for Hemp oil or CBD oil.

Considering the newness of industrial hemp farming, the process itself must be understood. We have created this tool for our customers to better understand both the timeline and the budgeting needed to make it through the initial seasons of farming hemp. Though we are not experts in hemp farming, the information we have gathered comes from industry experts. Be aware that the timeline dates may slightly vary depending on your farm’s geographic location. Budgeted estimates and action order may also vary depending on your specific crop, crop size, etc.

January

- Understand Hemp Types

- Do research around the differences in hemp strains before going into your first season. Hemp has a multitude of purposes, each with different strain types and growing methods. This research should include knowing where you will sell your crop, and what they require in regards to the product. (ex. maximum THC level, dry/wet, bucked material size, etc.)

- Buy Seeds – est. up to $2,500

- Though most farms do not propagate their own seedlings, this can be the more cost-effective method if your farm is capable of growing seedlings in a greenhouse or hydroponic garden. Only buy seeds from reputable sources.

- Buy Hemp Farming Registration – est. up to $2,600 depending on state

- Following the Farm Bill (2018) states were able to establish differing costs for registration of hemp farms. Check your own state’s regulations regarding growing and/or processing hemp.

- Perform Soil Test – est. $100 / sample

- Shop/Compare Equipment – Cost Varies

- Hemp farming requires machinery not used in most farms. Berry & melon farmers may already have some of the necessary equipment, but most farmers new to the industry will need the following:

- Mulch Layer - Available at Elite Metal Tools, Mulch Layers are pulled behind tractors generally above 50 HP. They are used to lay plastic mulch over the planting beds to provide a moisture barrier and act as weed control.

- Transplanter - Available at Elite Metal Tools, transplanters come in a variety of sizes capable of transplanting propagated seedlings into the ground at different row widths and spacings.

- Depending on your buyer’s requirements, you may need to purchase early processing equipment to meet their standards:

- Bucker - Availible at Elite Metal Tools, Buckers (aka De-Budders, Shuckers) separate the flower and buds from the stems. Stems are generally used for fiber production, whereas the flower and buds are processed to obtain the oils.

- Dryer - Industrial dryers can be used as an alternative to open air drying.

- Harvester - Harvesters are used to remove the entire plant from the field.

- Hemp farming requires machinery not used in most farms. Berry & melon farmers may already have some of the necessary equipment, but most farmers new to the industry will need the following:

February

- Till Field

- Preliminary cultivation of your field will always improve your crop. The cost of this may vary depending on your own farm operations.

- Fertilize Per Soil Test – est. $300 / acre

- Depending on the results of your samplings, fertilizing accordingly and early will improve your soil’s nutrient content. The cost of fertilizing will vary depending on field size and condition of your soil. For reference, hemp grows best in deep soils rich in organic matter with a pH from 6.0 to 7.5. Wetter soils can restrict shoot growth. Cost is dependent on what fertilizer you require and how much

March

- Buy Plastic Mulch – est. $400 / acre

- Plastic mulch is a plastic sheeting that acts as a weed barrier and moisture barrier. It is recommended to us 1.25mil thickness at 2’ or 4’ wide. The width needed can vary depending on your hemp strain and how much space they need for full development. It is generally understood that you will need 4,000’ per acre.

- Buy Drip Tape – est. $200 / acre

- Drip tape is a low-pressure tubed irrigation line that provides water to your soil and hemp. The holes, or emitters, in drip tape are generally spaced at 12” with a flow rate of .45 GPM per 100ft at 8 PSI up to 500ft. Depending on your soil and plant spacing, you may need different specifications.

- Buy Irrigation Components – est. up to $1,000 / acre

- Other components such as filters, a pressure regulator, a fertilizer injector, etc. are needed to complete your irrigation system. The price to establish your irrigation system may vary if running new water lines to your field.

- Research and/or Order Hemp Plugs – est. $250 / acre

- If your facilities are not capable of germinating hemp seedlings you will need to purchase plugs. In order to be prepared for transplanting in June, pre-ordering your plugs will ensure you will get your seedlings in time.

April

- Receive Necessary Equipment

- Being such a new industry, the equipment needed to farm hemp is in high demand. It has been common for hemp farmers to make last-minute equipment purchases, leaving them waiting up to 2 extra months. Make sure you order your equipment early.

- Buy Propagation Trays – est. up to $300 / acre

- Propagation trays are where you plant your seeds to begin the growing process. Your seedlings in the propagation trays, once sprouted, are called plugs. This cost varied depending on the density of your crop.

May

- Begin Propagating Seedlings

- If your facilities are capable of germinating your crop in propagation trays, now is when you should begin the growing process. The cost is dependent on labor and current facilities.

- Prepare the Seed Bed

- Your seed bed should be irrigated and weeded prior to laying your drip line and plastic mulch. The cost to prepare your beds are dependent on your current equipment.

- Install Drip Tape & Plastic Mulch

- You will need a tractor with at least 50 HP and your plastic mulch layer equipment to install your mulch. Drip tape can be installed sub-surface (buried) or between the soil and mulch. It is best to research your soil and crop and irrigate accordingly. Cost is dependent on labor and current equipment.

June

- Transplant Seedlings

- Transpanting your propagated seedlings to the field is done with your transplanting equipment behind a tractor. Depending on your equipment, your tractor requirements may vary. Cost is dependent on your transplanter capabilities and labor size required.

- Depending on your soil, climate, hemp strain, and equipment size and capabilities, your row spacing and plant spacing may vary greatly. Research the best method for your own farm and hemp type before spacing plants.

- Finish Irrigation Setup

- Connect your drip tape to your sub-mainline. Then proceed to check your irrigation’s pressure regulator, filters, etc. Check for potential blow-outs in higher pressure zones such as connections and tape ends.

- Early Weed Control

- Use a tool bar cultivator until your plants are too large.

- First Fertilization – est. $300 / acre

- Two weeks after planting.

July

- Monitor Irrigation

- Throughout the entire growing process, you should frequently check your irrigation system for leaks, blowouts, etc.

- Weeding

- Weeding should always be a part of daily farming activities. Since hemp reacts differently to common weed control chemicals, equipment is sometimes necessary to weed large crops.

- Fertilization – est. $200 / acre

- Based on your plant’s growth stage, fertilize with different compositions.

August

- Monitor Irrigation

- Throughout the entire growing process, you should frequently check your irrigation system for leaks, blowouts, etc.

- Weeding

- Weeding should always be a part of daily farming activities. Since hemp reacts differently to common weed control chemicals, equipment is sometimes necessary to weed large crops.

- Fertilization – est. $200 / acre

- Based on your plant’s growth stage, fertilize with different compositions.

- Scout and Remove Masculine Plants

- In many cases, you will need to remove masculine variants of hemp after they have pollinated the feminine variants. There are other options when looking at feminine vs masculine hemp plants as well as the post-harvest purposes of them. Do your research and choose the best option for your crop.

September

- Scout and Remove Masculine Plants

October

- Cut Hemp

- Depending on your location and stage of growth, this may occur in September or early October. There are many options at the late stages of farming hemp. Removing the plants from the field can be done with special equipment or by hand. You should be aware that buyers may require different end-product states. This may change the way you choose to cut the hemp.

- Dry Hemp

- If your buyer requires dried hemp, there are different options to do so. The most effective is air-drying. This is done in large greenhouse spaces, barns, or warehouses where the hemp is hung to dry. Industrial driers are another option. Driers have proven to be a less reliable option in the early years of the industry, but are still a great option with limited space. Outdoor air drying is the least tested method, however it has shown good results. It is becoming more popular in dry southern states such as Texas. Do research during the growing season to find the best method for your crop.

- Monitor Hemp Moisture Levels

- Frequently check the moisture content levels of your hemp to be within the guidelines set by your buyer. It is frequently between 8% to 12%.

- Harvest / Pre-Process Hemp

- In most cases, buyers will only take product that has been pre-processed. This is generally called bucking, thrashing, or de-budding. It is the process in which you remove the flower and buds from the stem. This is done on both dry and wet hemp, depending on your requirements. It can be labor intensive without the proper machinery.