Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

Ferous Vs Non-Ferous Cold Saw - Let's Learn About

The Lets Learn About Series is an exercise in which we try to anticipate the most common questions as they relate to the purchase of machinery and accompany them with the answers. If you have a question that you think would be a good fit for this series please email insidesales@elitemetaltools.com.

A Comparison of Ferrous Cold Saws vs. Non-Ferrous Cold Saws: Which One Fits Your Needs?

Ferrous Cold Saws: Ferrous cold saws are specifically designed to cut through ferrous metals, such as iron and steel. Here are some key features and advantages of ferrous cold saws:/product/12117

1. Cutting Capacity: Ferrous cold saws are built to handle the dense and tough nature of ferrous metals. They are equipped with powerful motors and robust blades that allow for efficient cutting of thick steel pipes, solid bars, and other ferrous materials.

2. Blade Composition: The blades used in ferrous cold saws are typically made of high-speed steel (HSS) or carbide. These materials offer excellent durability and heat resistance, enabling prolonged cutting sessions without compromising precision.

3. Blade Speed: Ferrous cold saws generally operate at lower blade speeds compared to non-ferrous cold saws. The slower blade speed helps maintain cutting stability and prevent excessive heat buildup when working with ferrous metals.

4. Coolant Systems: Due to the higher heat generated when cutting ferrous metals, ferrous cold saws often incorporate effective coolant systems. These systems help dissipate heat, reduce blade wear, and maintain cutting accuracy throughout the process.

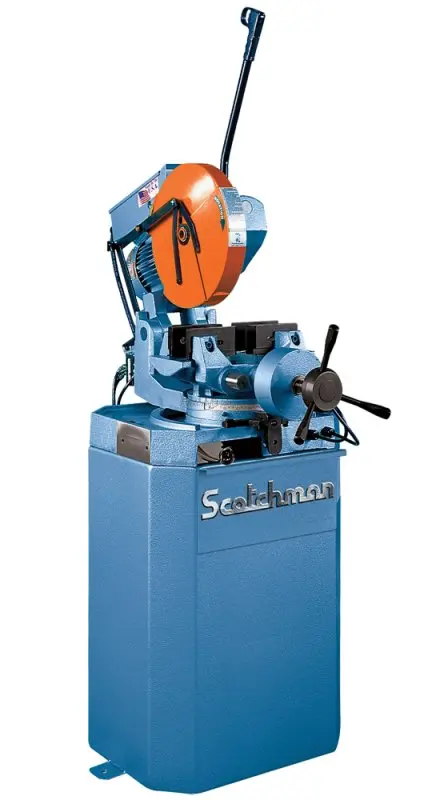

Non-Ferrous Cold Saws: Non-ferrous cold saws are designed specifically for cutting non-ferrous metals, such as aluminum, brass, and copper. Here are some key features and advantages of non-ferrous cold saws:https://www.elitemetaltools.com/tool-shop/products/scotchman-manual-non-ferrous-circular-cold-saw-cpo-350-nf?sku=076720

1. Blade Design: Non-ferrous cold saw blades have a different tooth geometry compared to ferrous saws. They feature finer teeth and a higher tooth count to achieve smoother cuts on softer metals without causing excessive vibration or material distortion.

2. Blade Material: To effectively cut non-ferrous metals, the blades of these saws are commonly made from tungsten carbide or cermet. These materials provide excellent cutting performance and prolonged blade life when working with softer metals.

3. Blade Speed: Non-ferrous cold saws generally operate at higher blade speeds compared to ferrous cold saws. The increased blade speed allows for faster cutting rates and helps prevent material buildup and chip clogging when working with non-ferrous metals.

4. Chip Collection Systems: Non-ferrous cold saws often incorporate chip collection systems to handle the specific challenges posed by non-ferrous metal cutting. These systems effectively capture and remove the chips generated during the cutting process, ensuring a clean work area and preventing chip buildup.

Considerations and Conclusion: Before choosing between ferrous and non-ferrous cold saws, there are a few considerations to keep in mind:

1. Material Compatibility: Consider the primary type of metal you work with. If your projects mainly involve ferrous metals, a ferrous cold saw is the optimal choice. Conversely, if non-ferrous metals are predominant, a non-ferrous cold saw would be more suitable.

2. Versatility: If you work with a wide range of metal types, you might consider investing in both ferrous and non-ferrous cold saws to ensure optimal cutting performance and efficiency across various materials.

3. Budget and Workload: Evaluate your budget and the volume of cutting work you typically handle. This will help determine the level of investment required and whether a specialized saw or a versatile option better aligns with your needs.

In conclusion, ferrous and non-ferrous cold saws are designed to cater to specific metal cutting requirements. By understanding their key differences, including blade speed, and considering factors such as the type of metal, versatility needs, and budget, you can make an informed decision to select the most suitable cold saw for your applications. Whether you need to cut ferrous metals or non-ferrous metals, there is a cold saw available to meet your specific cutting needs.