Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

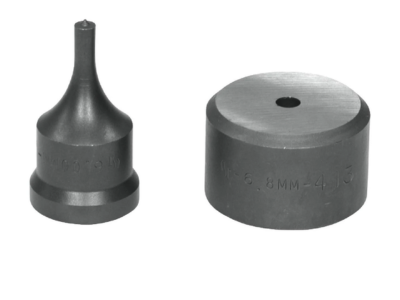

Exploring the Versatility of Punch and Die Sets for Ironworkers

1. Types of Punch and Die Sets: Punch and die sets are as varied as the tasks they perform. Standard punch and die sets are a staple in any metalworker's arsenal, ideal for basic hole punching operations. For more specialized tasks, oblong, square, and round punches enable the creation of diverse hole shapes. Offset dies are designed for specific applications, such as creating flanges or channels in metal sheets. Specialty dies, including notching, coping, and trimming dies, are tailored for intricate and complex metalworking tasks. Understanding the nuances of each type is essential for selecting the right set for each project.

2. Material Considerations: The effectiveness and longevity of punch and die sets are directly influenced by the materials they are made from. High-carbon steel sets offer durability and are a common choice for general use. High-speed steel sets provide greater hardness and are ideal for high-volume or high-intensity tasks. For the ultimate in wear resistance, carbide-tipped sets are the go-to choice, especially for working with tougher metals. The right material choice ensures that the punch and die set not only lasts longer but also delivers consistent, high-quality results.

3. Latest Innovations in Punch and Die Technology: The metalworking industry continually evolves, and punch and die technology is no exception. Recent advancements include multi-tool stations that increase the versatility of Ironworkers, quick-change mechanisms that reduce downtime, and automated alignment systems that enhance precision and reduce waste. These innovations streamline operations, improve safety, and boost productivity, making them invaluable in a competitive market.

4. Maintenance and Care of Punch and Die Sets: Proper maintenance is crucial for maximizing the life and effectiveness of punch and die sets. This section delves into the best practices for cleaning, storing, and handling these tools. It covers routine inspections, the importance of keeping the sets sharpened, and tips for preventing rust and corrosion. Regular maintenance not only extends the life of the tools but also ensures they operate at peak efficiency.

5. Choosing the Right Punch and Die Set for Your Ironworker: Selecting the appropriate punch and die set for an Ironworker machine can be a daunting task. This guide simplifies the process, outlining key considerations such as machine compatibility, material thickness, desired hole size and shape, and the specific requirements of the task at hand. This section aims to empower buyers with the knowledge to make informed decisions, ensuring they get the most out of their investment.

6. Case Studies or Success Stories: Real-world applications bring the capabilities of punch and die sets to life. This segment features case studies and success stories from various industries, demonstrating how the right tools have led to improved efficiency, precision, and problem-solving in metalworking projects. These stories not only illustrate the practical benefits of quality punch and die sets but also inspire confidence in potential customers.

7. Comparison with Other Metalworking Tools: In this comprehensive comparison, punch and die sets are pitted against other common metalworking tools such as laser cutters, plasma cutters, and shears. The comparison highlights the unique benefits of punch and die sets, particularly in terms of cost-efficiency, speed, and versatility, offering valuable insights for those weighing their tool options.

8. Safety Tips for Using Punch and Die Sets: Safety is paramount in metalworking. This section provides essential guidelines on using punch and die sets safely, including the use of appropriate protective equipment, proper machine operation techniques, and emergency response procedures. By adhering to these safety practices, workers can minimize the risk of accidents and injuries.

9. Industry Applications of Punch and Die Sets: The versatility of punch and die sets is showcased in this exploration of their applications across various industries. From construction and automotive manufacturing to aerospace and general manufacturing, these tools play a critical role in numerous sectors, underscoring their importance in the broader context of industrial production.

10. FAQs or Common Misconceptions: This final section addresses frequently asked questions and dispels common misconceptions about punch and die sets. Providing clear, accurate information helps potential customers better understand these tools and their capabilities, fostering informed decision-making.

Conclusion: Punch and die sets are indispensable in the metalworking industry, offering unmatched versatility and precision. With the right selection, maintenance, and application, these tools significantly enhance the capabilities of an Ironworker machine. As the industry continues