Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

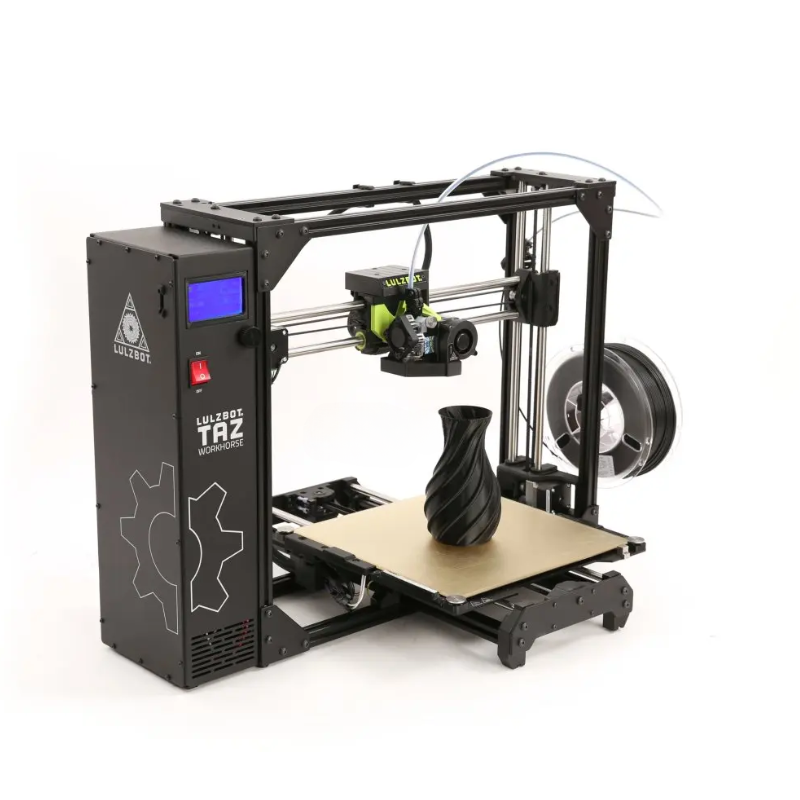

The Evolution and Impact of 3D Printing in Prototyping

History of Additive Manufacturing and Prototyping

Additive manufacturing, the process of creating objects by adding material layer by layer, has its roots in the 1980s. Initially, it was a tool for rapid prototyping, allowing engineers and designers to quickly produce physical models from digital designs. This sped up the development process significantly, bypassing the lengthy and often costly traditional manufacturing methods. Over the years, advancements in technology have transformed 3D printing from a prototyping aid into a robust manufacturing solution, embraced across industries from aerospace to healthcare.

Materials in 3D Printing for Prototyping

The choice of materials in 3D printing is critical, as it determines the prototype's properties and usability. Early 3D printers primarily used plastics like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid), known for their ease of use and versatility. However, the scope of materials has broadened dramatically. Brands like LulzBot and FlashForge now offer printers that work with a wide range of materials, including flexible filaments, composites, and even metals, allowing for more durable and functional prototypes.

Current Trends and Innovations

The 3D printing industry continues to evolve rapidly, with trends focusing on increased speed, larger print volumes, and greater precision. FlashForge and Hyrel 3D are at the forefront, offering advanced printers that cater to these evolving needs. Moreover, the integration of AI and machine learning in 3D printing software is streamlining the prototyping process, making it more efficient and less prone to errors.

Cost-Effectiveness and Efficiency

One of the most significant advantages of 3D printing in prototyping is its cost-effectiveness. Traditional prototyping methods often require expensive tooling and machinery, whereas 3D printers like those from Dremel can produce complex designs at a fraction of the cost and time. This efficiency not only reduces the product development cycle but also allows for more iterations and improvements.

Environmental Impact

Sustainability is another aspect where 3D printing shines. Additive manufacturing minimizes waste compared to subtractive methods, as it only uses the material needed to build the prototype. This eco-friendly approach is increasingly important in today's environmentally conscious market.

Future Outlook

The future of 3D printing in prototyping is incredibly promising. We are likely to see further advancements in printer technology, material science, and software capabilities. This evolution will continue to enhance the efficiency, precision, and applications of 3D printing in various sectors.

Conclusion and Summary

3D printing has undeniably transformed the landscape of prototyping, offering unparalleled speed, flexibility, and cost savings. Brands like LulzBot, FlashForge, Hyrel 3D, and Dremel are leading this change, continuously innovating to meet the demands of modern product development. As we look to the future, it is clear that 3D printing will continue to play a pivotal role in shaping the world of design and manufacturing, driving innovation and efficiency across industries.