Elite Metal Tools Articles

Industry news, tips, and updates on all things Elite Metal Tools

Choosing the Right Press Brake

For many shops or businesses, a press brake is crucial during production. Press Brakes, like band saws, shears, and sanders, are industry standards on a shop floor—so when choosing a machine for your shop or business, there are many things to consider to assure it is the best press brake for you.

Press Brakes are generally hydraulically or pneumatically-driven pressing tools used to bend sheet metal or plate. They are common among shops and businesses fabricating pieces such as brackets, HVAC systems, flashing, or any finished product that requires angled sheet metal or plate. Its mechanics are very similar to the operating movements of a hydraulic press. Bends are achieved from vertical force applied to the workpiece between a matching punch and die. Like hydraulic presses, a press brake’s tooling is held on the stationary table of the machine and the moving upper beam. All tooling is different depending on the desired final results.

Materials

Whether you have a small fabrication shop or a high-volume operation, you probably work with only a handful of specific metals and materials. This is the first, and most important consideration when choosing a press brake. Knowing the type of metal (carbon steels, alloy steels, aluminum, stainless steel, etc.) as well as other characteristics such as gauge, length, and treatments—which can increase the tensile strength of some metals—help determine the tonnage and size requirements for your press brake. These characteristics can be learned from your metal and material providers; note that the most important information regarding your material is its tensile strength.

Tooling

There are 90 degree dies, acute dies, hemming dies, gooseneck dies, offset dies, and much more that all perform different bends. Understanding the tooling requirements for your specific project can narrow your search for the right machine. It is important to do your research before buying new tooling for your machine—dies are not only designed to make certain bends, but also designed to bend materials with certain lengths, widths, gauges, and tensile strengths. Like the machine, tooling also has limits; stretching those limits can damage your machine, damage your workpiece, or cause harm to the operator. Tooling is also not always compatible along all press brake platforms, and should be discussed either with your supplier or the manufacture. If you have existing tooling, are purchasing tooling from the manufacture, or purchasing tooling through a third party, make sure the tooling is capable of handling the desired tonnage.

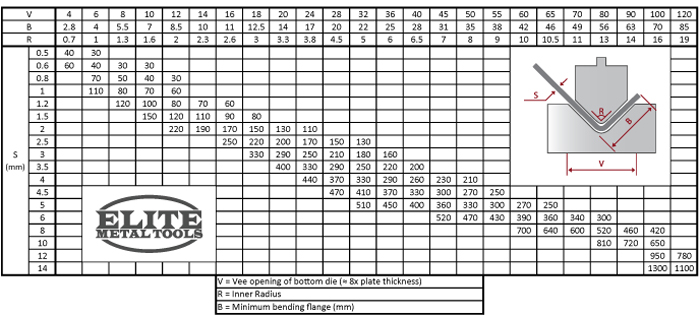

Tonnage

The most common mistake when purchasing a press brake is miscalculating the amount of tonnage needed to complete your bends. Though buyers frequently underestimate their tonnage needs, it is just as common to overspend for a larger machine. Calculating tonnage is as simple as utilizing a press brake tonnage chart—preferably provided by the manufacture. The chart provided (Fig. 1.1) is a basic calculation for bending metal with a tensile strength similar to mild steel. Most metal types have specific tonnage calculations and charts that can be found online. If you are unable to find calculations for your material, give us a call and we would be more than happy to discuss your needs and find the right machine for you.

Open Height

Open height, also referred to as “daylight”, is the space between the tooling when operating the machine. This is a small but crucial detail to explore when choosing a machine. While standard open heights work for most bending applications, more complex bends with larger flanges may require a larger open height. The open height may also be a factor when using customized or unique tooling. If your desired open height is unknown, choosing a machine with a large open height is a safe option since the majority of machines have an adjustable stroke length.

Price & Brand

The final factors to consider when choosing a press brake are fairly standard when choosing any piece of machinery. The first of these is price—we understand that your business or shop must make sound financial decisions when adding equipment and tools. Because of this, Elite Metal Tools has made an effort to provide a wide selection of machinery at prices suitable for any size shop or business. Machine prices are determined by a few factors. The first, and most important of these is the tonnage output. Higher-ton machines require far more reinforcements and a higher durability standard. The higher the tonnage output, the higher the price. the next price-determining factors are build quality and features. Some press brakes boast CNC controls, DRO’s, all-steel rams and beds, steel reinforcements, and low error margins. Such features and specifications add value, versatility, and strength to the machine. The last notable determining factor of machine price is the brand. Well-known brands often come at a higher price due to a higher demand, unique feature, or better build quality. Brand recognition is also a reason many choose a specific brand, however, more often than not, well-known brands are popular because they simply make good, reliable machines.

Choosing the right machine for your shop or business is what we do here at Elite Metal Tools. If you are looking for new equipment, we have the perfect machine for your shop of business. We offer the largest selection of industry-leading metalworking machines including abrasive chop saws and cold saws. Not sure what you need? Call one of our knowledgeable team members at (281) 241-9504 or email us at insidesales@elitemetaltools.com