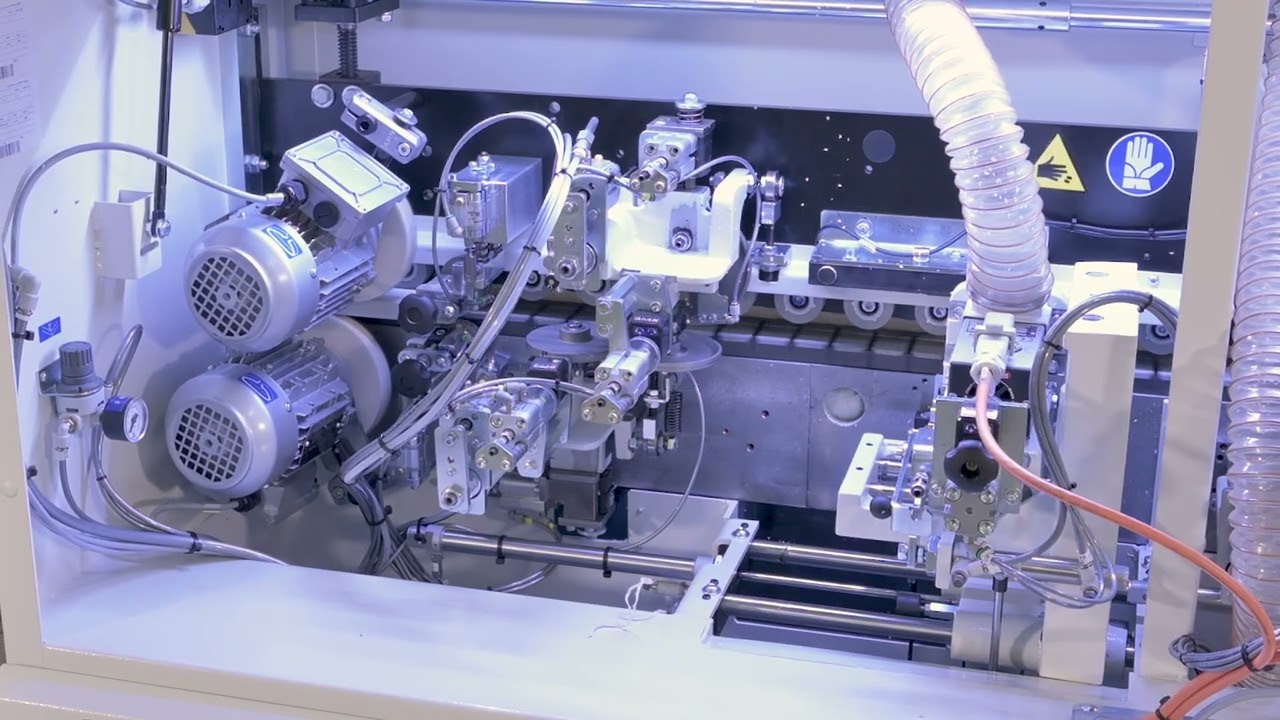

Anti-Adhesive Unit

It prevents the glue sticking to the upper and lower panel surfaces through improving the cleaning. This unit is complete with two spraying guns and tank for the antiadhesive liquid

Pre-Milling Unit

Complete with (2) diamond tools, 80mm diameter. It allows a very good panel finish and linearity during pre-machining. It is equipped with independent exhaust hoods and an air blower which cleans the panel from dust and chips. It is possible to carry vertical adjustments of the tools to use them even in the final sharpening phase

Glue Pot Unit, Edge Loading and Pressing System

- Hot melt glue with quick heat up system and internally teflon coated to allow an easy glue replacement

- Glue application on the panel by means of glue spreading roller

- Temperature adjustment of the applied glue integrated in the PLC control

- Device for automatic recovery of unused glue

- Automatic edge loading system for rolled edges with shear device for 3mm max thickness edges

- Coil holder plate, 730mm diameter

- Pressing unit with n. 2 edge steel rollers with counterposed conicity

- Adjustable infeed fence with numeric readout

- Automatic lowering of the glue pot temperature after a temporary non-use of the machine

- Self-lubrication system of the glue pot

Top/Bottom Trimming Unit with Multiradius Tool

- High frequency motors

- Front rotating copiers with chrome plated surfaces and vertical copying discs for an accurate positioning of tools with reference to the cutting point

- Pneumatic on/off system controlled by the Eye-S panel

- Trimming unit capable of processing 1 and 2mm edge thicknesses with automatic set-up controlled by the Eye-S panel. For the machining of thin edges and between 1 and 2mm, it is foreseen a manual adjustment

Rounding Unit

High frequency motor controlled by the Eye-S panel

Edge Scraping Unit with Multiradius Tool

It assures an excellent vibration free finish thanks to its high rigidity structure. High working precision thanks to the horizontal and vertical copying discs which assure an accurate positioning of the knives in relation to the cutting point. Capable of processing 1 and 2mm edge thicknesses with automatic set-up controlled by the Eye-S panel

Glue Scraping Unit with Automatic On/Off

Glue scraping unit with rotating copying device. It eliminates any excess of glue in the joint between panel and edge improving the panel cleaning

Brushing Unit

Tilted, vertically adjustable motors to optimize the cleaning and polishing of the edge

Features

- “Eye-S” Compact Console: optimal managing of the machine thanks to the new 10” touch screen control panel with Maestro active edge, where all of the machine functions are graphically shown

- Rounding Unit-Unmatchable Finish: rounding unit with rigid structure for a unique quality of work in its segment

- Flexibility and Ease of Use: trimming unit and scraping unit with multiradius tool pneumatic on/off system of the units controlled by the Eye-S panel

- Safety/Protections

- Safety enclosure

- Main power switch can be locked in the off position with a padlock

- Emergency pushbutton located on the control panel

- Encoder positioned on the panel feed track pinion

Standard Equipment

- Eye-S 10” touch screen control on machine infeed side

- Maestro active edge interface

- Immediate and intuitive panel programming thanks for the adaptive 3D design of the processing the real time preview

- No possibility of error with the machining guidance system that suggests the correct machine set up to the operator

- Main frame made of bended and welded steel plates to ensure a high rigidity structure

- Top steel presser, complete with two rows of rubber coated wheels mounted on bearings and enclosure that covers the wheels

- Manual adjustment of top beam with automatic positioning of the operating units according ot the selected panel thickness

- Kit for glue pot rapid substitution which includes the rapid locking/unlocking device and the double thermoregulation system to manage two different working temperatures

- Numeric indicator of the selected panel thickness

- Feed track made of pads coated with high friction rubber fixed on n ¾ industrial chain. Sliding of pads on two guideways, one round and one flat, to ensure straightness of movement and resistance to side loads. Manual pads lubrication

- Panel support roller which can be extended on the entire length of the machine

- Units included: pre-milling, glue pot, end cutting, T/B trimming, rounding, profile scraping, glue scraping, buffing

- (2) pre mill diamond cutters, 2mm multiradius tooling set included

- Toolbox: wrenches, allen wrenches, user manual, spare parts catalog

Specifications

- Worktable dims: 136.37” x 27.94”

- Worktable height: 34.44”

- Thickness of rolled edges: 0.02-0.06”

- Thickness of edges in strips: up to 0.19”

- Panel Height: 0.31-1.94”

- Min panel length/width with rolled edges: 7.5”/4.31”

- Feed speed: 30 fpm

- Feed motor power: 0.55 kW

- Operating temperature: 68-374° F

- Pre-Milling Unit

- Motor: 3 kW – 7,200 rpm

- Diamond cutter: 2 x Ø 80mm H=56 Z2

- Stock removal: 0-0.08”

- Glue Pot Unit

- Motor: 0.25 kW

- Glue Capacity: 2 lbs

- End Cutting Unit

- Motor: 0.19 kW – 12,000 rpm

- Blade: Ø 125mm Z2

- Top and Bottom Trimming Unit

- Motor: 2 x 0.35 kW – 12,000 rpm

- Widia cutters: Ø 55.3mm Z3

- Rounding Unit

- Motor: 0.35 kW – 12,000 rpm

- Cutter: Ø 58mm Z4

- Brushing Unit

- Motor power: 2 x 0.14kW – 2,800 rpm

- Exhaust outlets diameter

- no. 2 pre-milling unit outlets: 3.12”

- no. 1 glue pot outlet: 3.12”

- no. 1 rounding unit outlet: 2.31”

- no. 2 trimming unit outlets: 2.31”

- Nominal extraction air consumption: 1,082 CFM

- Air exhaust speed: 66 ft/s

- Pneumatic operating pressure: 6.5 bar

- Electrical Requirements: 220V Three Phase 60Hz 38A

- Machine Dims: 146” x 41” x 69”

- Approx Weight: 2,400 lbs

Optional Add-Ons

- Single Phase Version (please contact a sales rep for more info)

- Spare glue pot

- Spare glue pot for EVA glue with fast unloading system

- Spare glue pot for PUR glue with fast unloading system

- Device for the panel edge heating

- Infrared ceramic lamp

- Spray-mist device for delicate edges

- Spray-mist device for edge finishing

- Edges storage

- Edges storage with heating function

- Scoring unit for grooves execution

- Wireless barcode reader

**This machine requires a mandatory installation and training from the manufacturer. This comes as an additional charge that is NOT included in the website price. This additional charge includes the installation and full training on how to operate and maintain the machine. Please contact one of our sales representatives for more details**